Appearance

What is the Laser Cutting?

Detailed Explanation

To better understand, we can break it down into several key components:

- Core Principle: Using "Light" as a "Knife" Laser Generator: The heart of the machine, responsible for producing a very fine, high-energy laser beam. Think of it as a super flashlight, but the light it emits is coherent and highly directional.

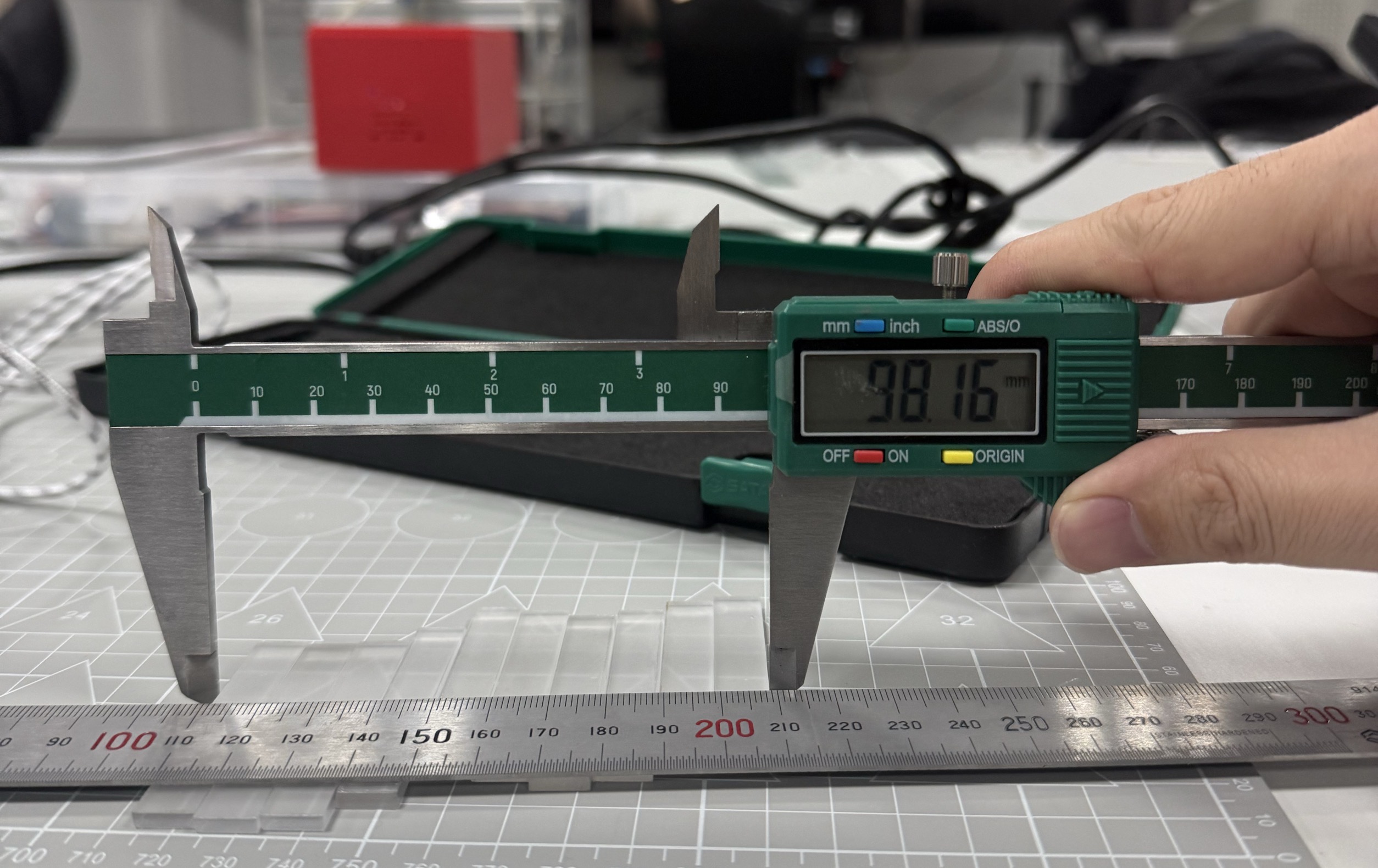

Focusing: The laser beam is focused through a lens or curved mirror into an extremely small spot (typically less than 0.5 mm in diameter), creating an extremely high power density at the focal point (e.g., several times the temperature of the sun's surface).

Interaction: When this high-energy spot irradiates the material surface, the material is rapidly heated, melted, or even vaporized.

Auxiliary Gas: Simultaneously, a high-speed gas flow (such as oxygen, nitrogen, or compressed air) is blown from a nozzle coaxial with the laser beam, removing the molten or vaporized material to form a clean, smooth cut.

- Components of a Laser Cutting System A typical laser cutting machine mainly includes:

Laser Generator: The device that produces the laser (e.g., CO₂ laser, fiber laser).

Cutting Head: Contains the focusing lens and gas nozzle, serving as the "end effector" for cutting.

Motion System: Typically a precision CNC machine tool that controls the cutting head to move along the X, Y, and Z axes according to a preset graphical path (e.g., a CAD file).

CNC System: The "brain" of the machine, which receives design drawings and coordinates the entire machine’s operations.

Cooling System: Cools the laser generator to ensure stable operation.

- Main Features and Advantages High Precision: Narrow kerf, precise cutting dimensions (up to ±0.1 mm), and excellent repeatability.

High Flexibility: Controlled by software, it can easily cut any complex shape without the need for mold changes. Ideal for small-batch, diversified production.

High Speed: For thin sheet materials, cutting speeds are extremely fast, far more efficient than traditional methods.

Excellent Cut Quality: Smooth edges, no burrs, and minimal need for secondary processing.

Non-Contact Processing: The cutting head does not touch the material, avoiding surface scratches and tool wear.

Wide Material Applicability: Capable of cutting various metals and non-metallic materials.

- Application Areas (Ubiquitous) Metalworking: The largest application area, used for sheet metal processing, automotive parts, chassis, cabinets, kitchenware, metal artwork, etc.

Advertising and Signage: Cutting acrylic (PMMA), dual-color boards, wood to create signs and logos.

Apparel Industry: Precise cutting of fabrics and leather for patterns and镂空 designs.

Electronics Industry: Cutting circuit boards (FPC), internal structural components of mobile phones.

Model Making: Creating architectural models, sand table models.

Medical Devices: Cutting精密 stents, surgical instruments.

- Limitations High Initial Investment: Industrial-grade laser cutting machines are expensive.

High Energy Consumption: High power requirements and the need for stable electricity during operation.

Material Limitations: Difficulty or danger in cutting highly reflective materials (e.g., copper, gold) and materials that produce toxic gases (e.g., PVC).

Thickness Limitations: Cutting capability decreases for very thick materials, reducing efficiency and precision

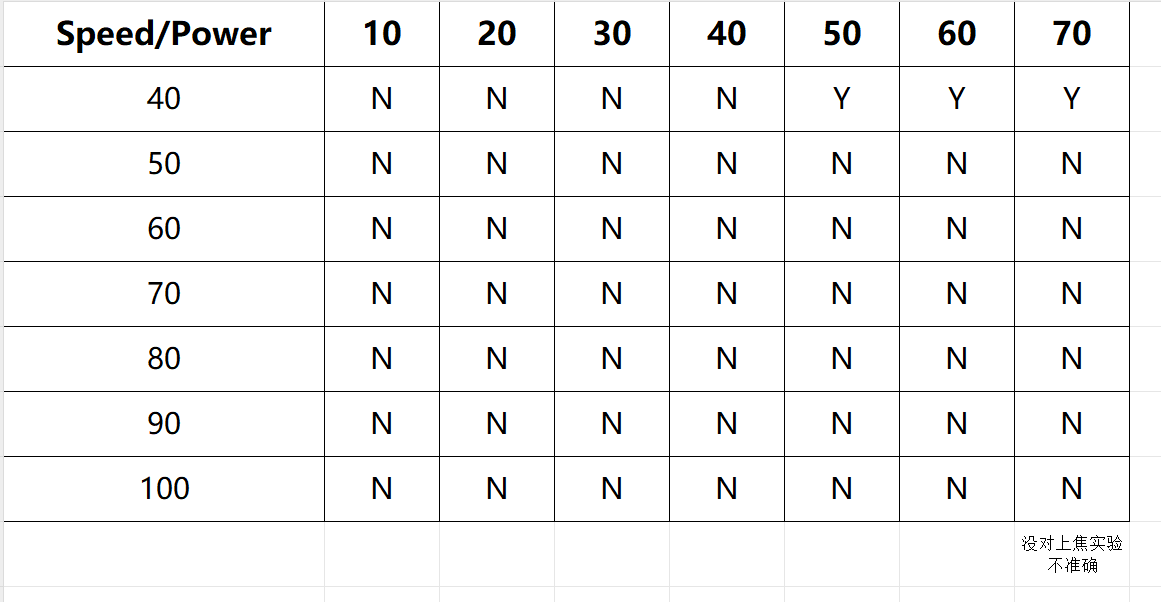

Operation process and icon of laser cutting machine

(1).jpg)

(1).jpg)