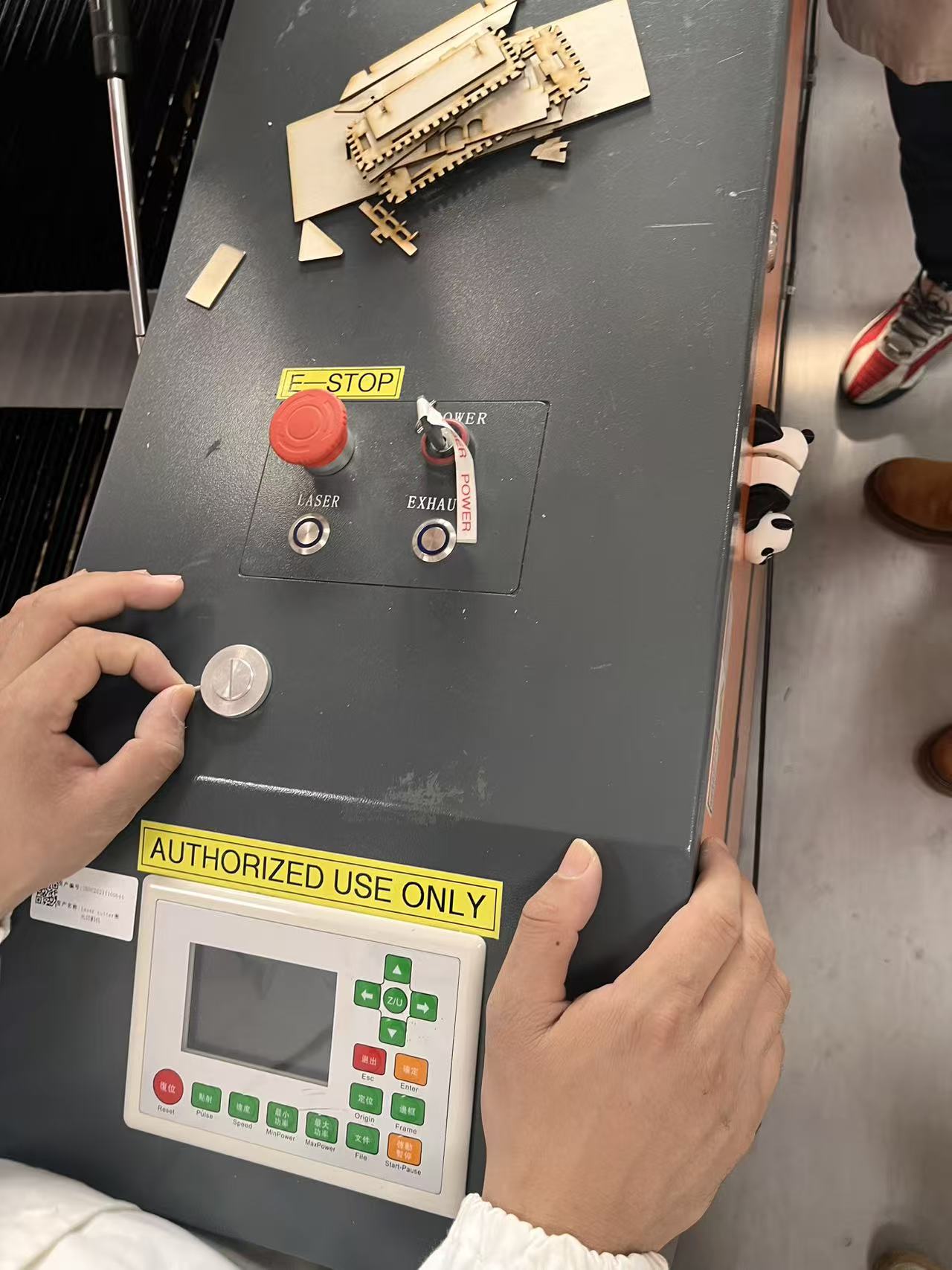

Laser Cutting Process

1. Equipment Overview

2. Typical Process Parameters

- Cutting: Speed 80 mm/s, Max Power 95%

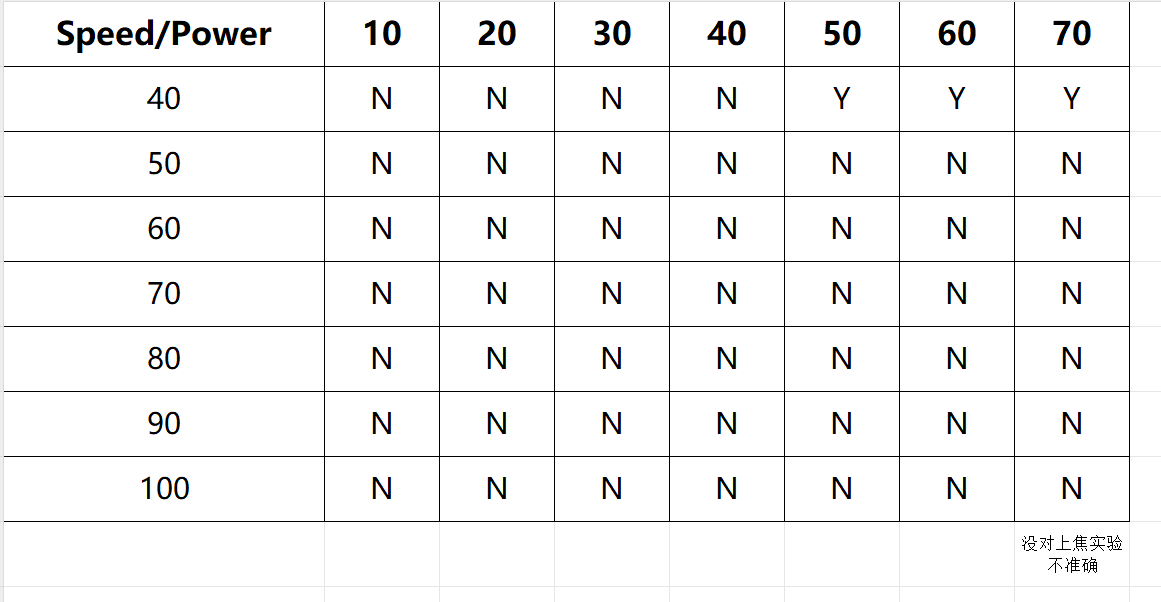

3. Power-Speed Matrix Test

Results indicate that insufficient power causes incomplete penetration, while excessive power or low speed produces significant heat-affected zones (HAZ) and carbonization.

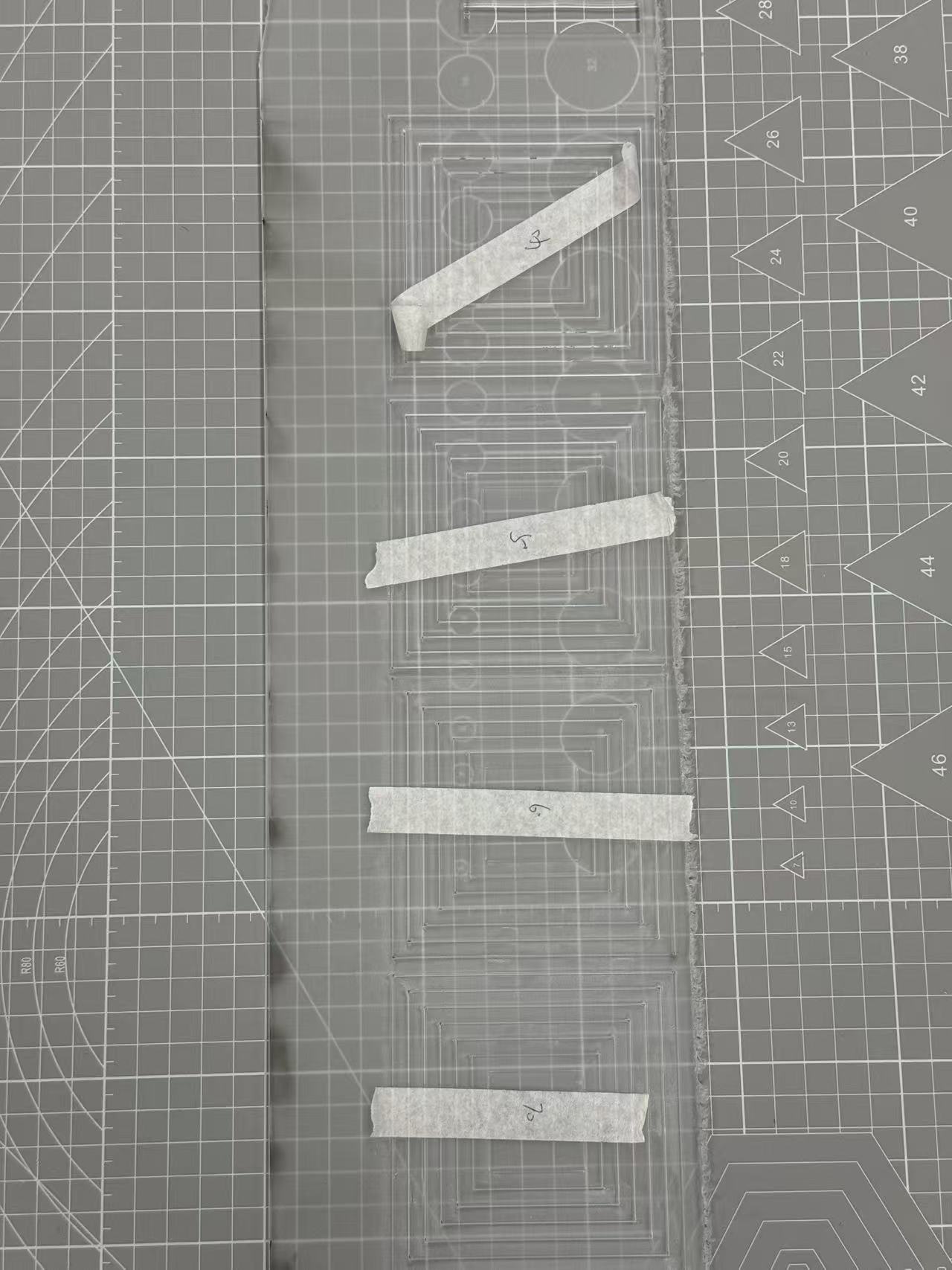

4. Influence of Focal Position

Due to incorrect focal position, beam spot diameter increased and power density decreased dramatically, resulting in failure to cut even at a relatively high power.

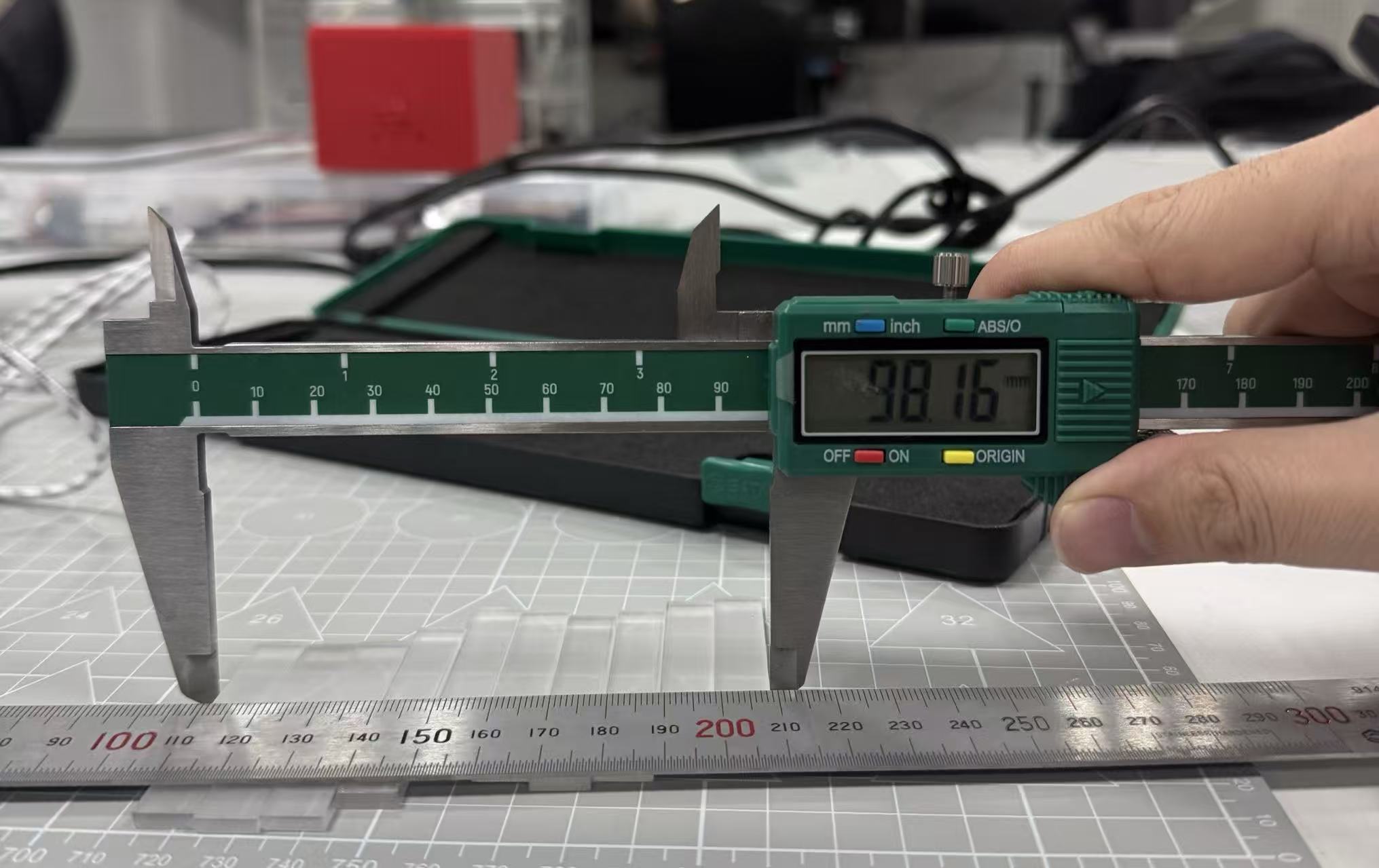

5. Kerf Width Measurement and Compensation

- Designed dimension: 100.00 mm

- Measured dimension: 98.16 mm

- Total material removal: 1.84 mm

- Kerf = 1.84 mm ÷ 10 = 0.184 mm