PCB Manufacutre

Experiment Overview and Objectives

This experiment involved the use of the Roland MODELA MDX-40, a compact desktop CNC milling and scanning machine, to investigate subtractive manufacturing on metallic or composite workpieces. The primary objectives were to evaluate machining precision, surface finish quality, and operational characteristics under typical laboratory conditions.

Equipment Description

The Roland MODELA MDX-40 features a fully enclosed transparent hood for safety and chip containment, with a red emergency stop button prominently positioned on the right side. The control panel includes dedicated buttons for power, modeling, scanning, and tool operations, reflecting thoughtful ergonomic design for desktop use. Image 1 provides a comprehensive view of the machine, highlighting its robust build and integrated workspace.

Tooling and Material Preparation

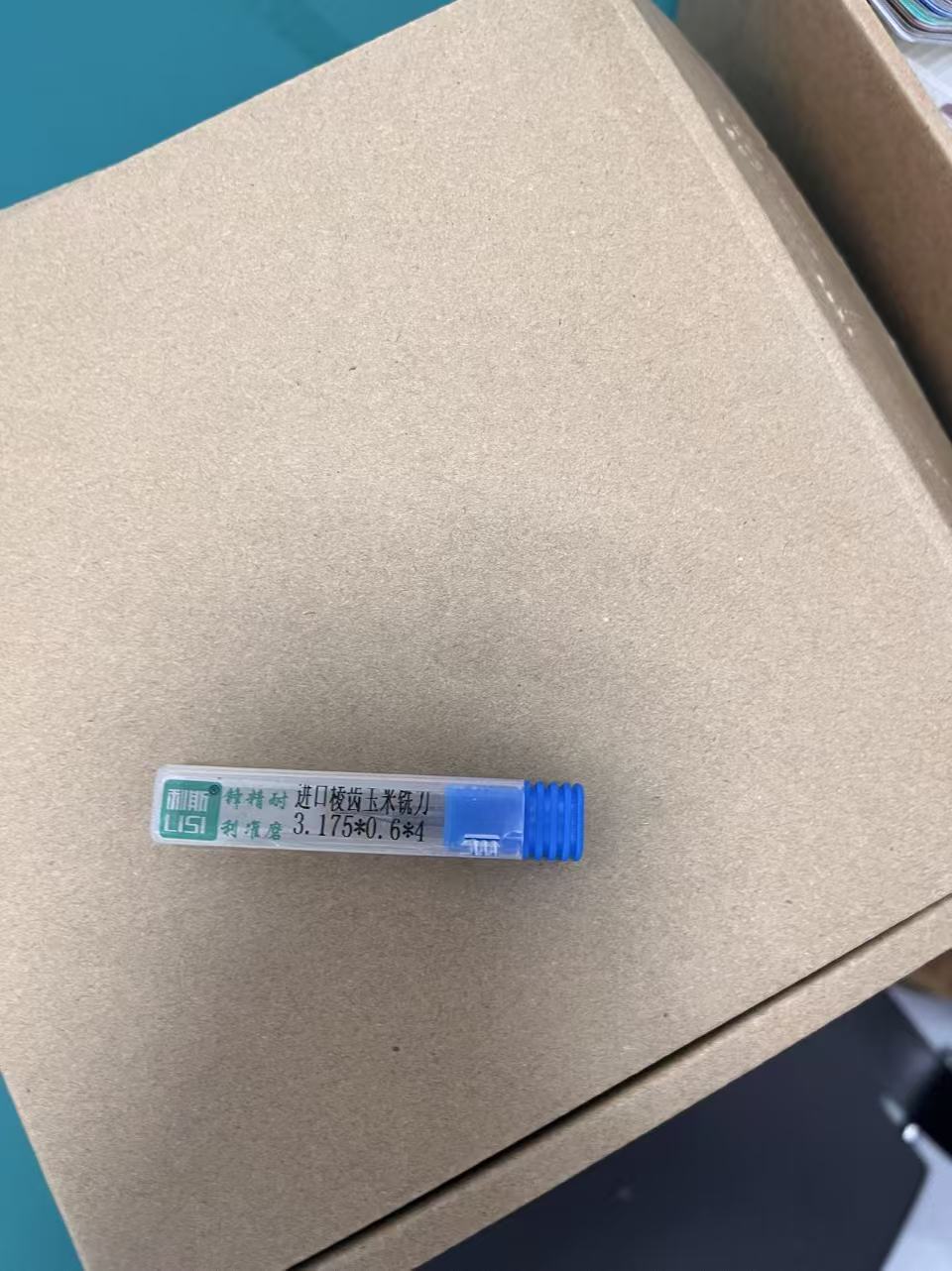

Tool selection is critical for achieving desired precision and finish. Image 2 shows a specialized end mill: shank diameter 3.175 mm, cutting diameter 0.6 mm, and flute length 4 mm. This fine-diameter flat-end mill is optimized for detailed features and high-quality surface finishes on softer metals or composites, with the blue protective cap ensuring safe handling.

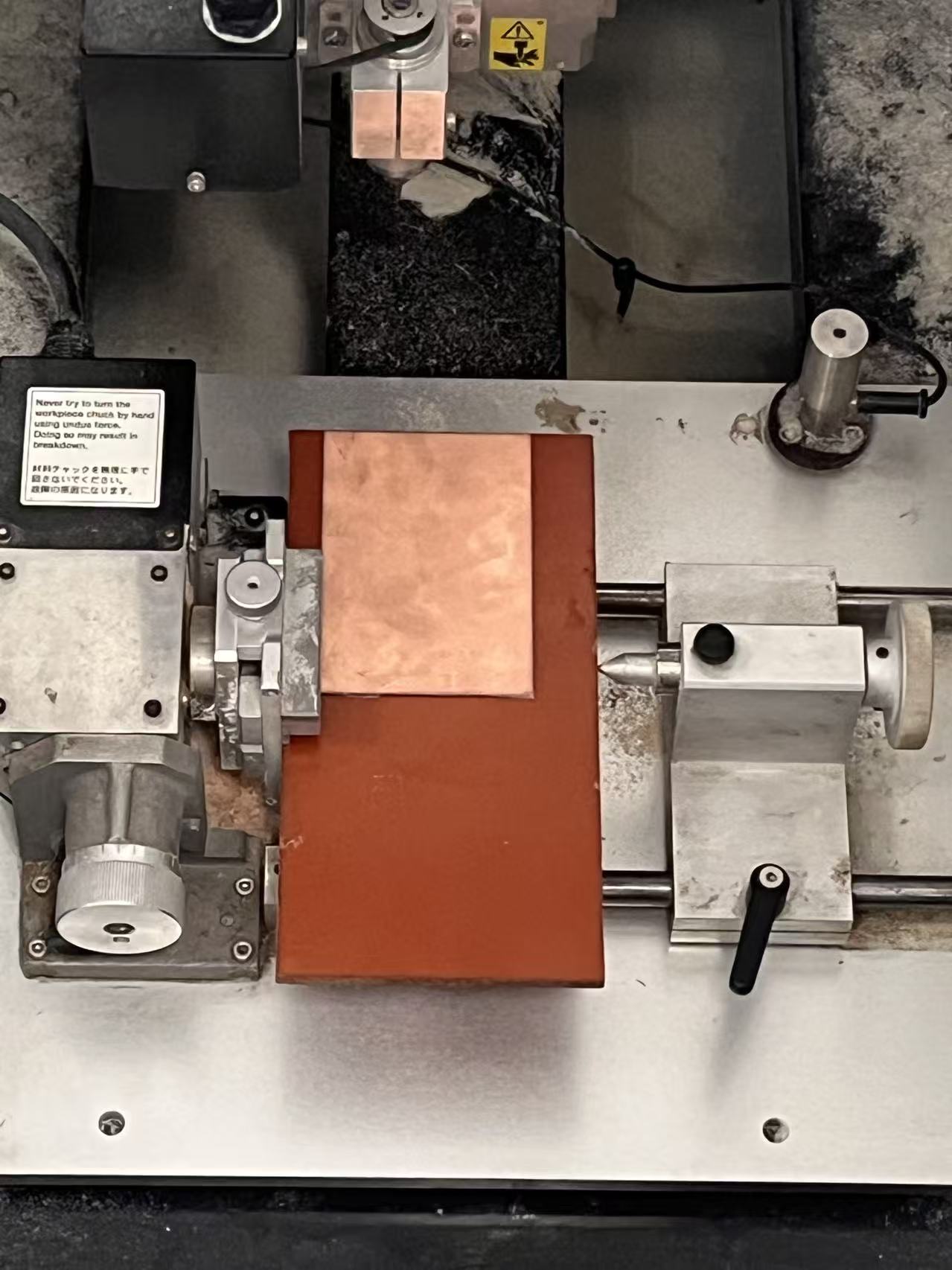

The workpiece visible in Image 3 appears to be a copper-colored plate fixed securely on the machine bed, exhibiting uniform machined texture indicative of controlled cutting parameters.