ABS was selected for its excellent impact resistance and moldability

Equipment and Materials Summary

- Machine: Benchtop injection molder with reliable clamping and precise heating zones.

- Mold: Single-cavity aluminum (hemispherical shape).

- Material: White ABS pellets.

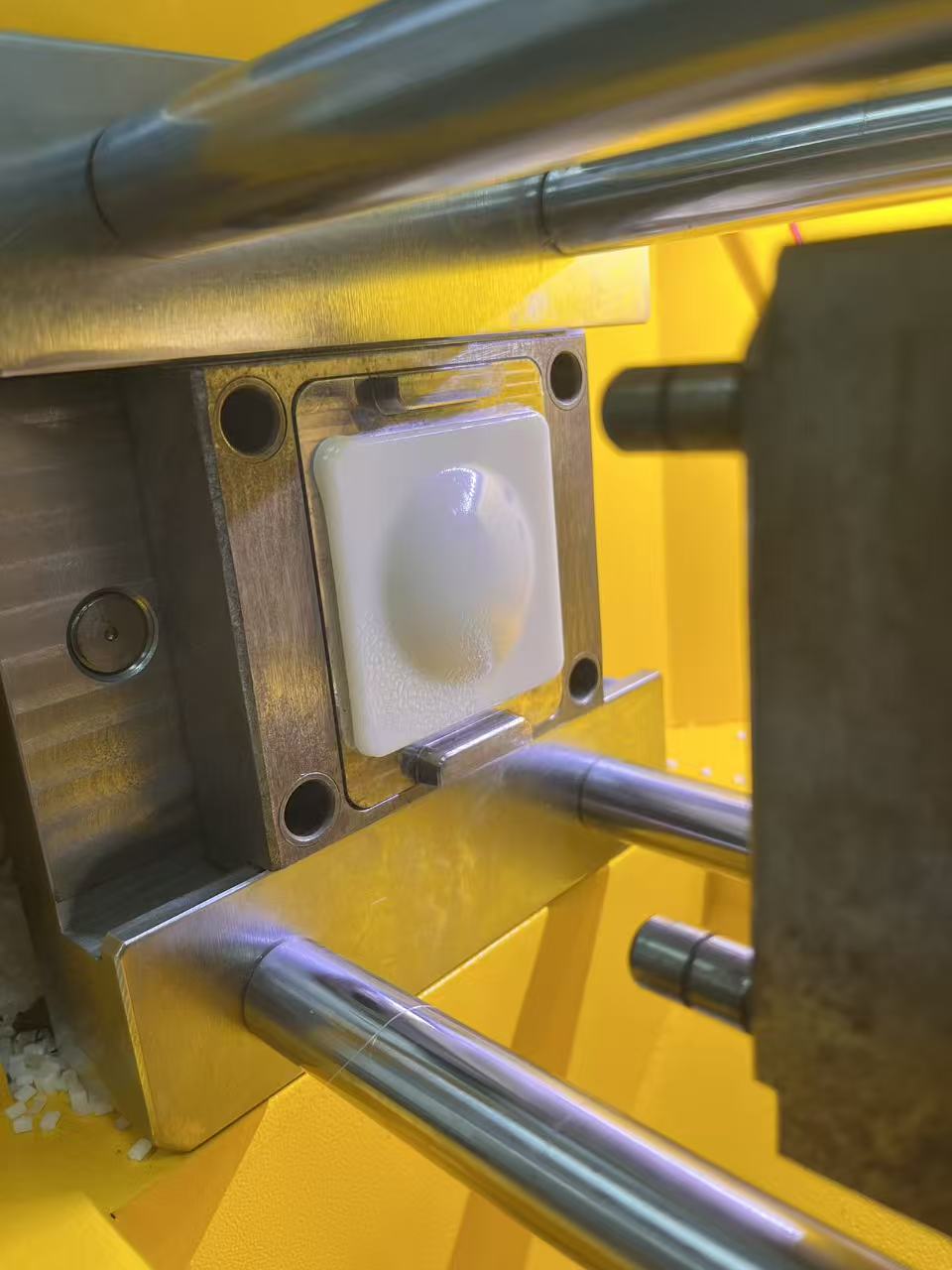

: Shows the mold opening post-injection, revealing a pristine hemispherical part.

: Shows the mold opening post-injection, revealing a pristine hemispherical part.

Detailed Process Workflow with Recorded Parameters

1. Material Preparation (Drying Phase)

Moisture absorption in ABS can cause voids or surface haze—pre-drying is non-negotiable.

- Drying temperature: 85°C (gentle to prevent degradation).

- Drying duration: Approximately 2.5 hours. Personal note: Skipping or shortening this step once led to subtle surface blemishes in a trial run; restoring full duration resolved it completely.

2. Mold Setup and Clamping

- Secure the aluminum mold on the platform, aligning perfectly with the four guide pillars.

- Apply uniform clamping force to prevent flash during high-pressure injection.

3. Melting and Injection Phase (Core Parameters)

Temperature zoning and injection dynamics were iteratively refined for optimal fill:

- Zone 1 temperature: 180°C (pre-melt for uniform plastication).

- Zone 2 temperature: 220°C (injection zone for superior flow).

- Injection duration: 6.5 seconds (precise timing to avoid overpack or short shots).

These settings ensured smooth material flow into the hemispherical cavity without turbulence.

4. Cooling, Demolding, and Part Extraction (Image Focus)

- Cooling method: Ambient air cooling (2-3 minutes).

- Demolding highlight (the defining moment):

- Smooth mold separation reveals a fully formed white hemisphere retained cleanly in the cavity.

- Surface exhibits mirror-like gloss with minimal gate marks and no visible warpage, shrinkage, or flow lines.

- Clean release indicates excellent mold surface finish and balanced cooling.

Personal Reflections and Improvement Strategies

- Parameter Sensitivity: A 10°C increase significantly boosts flow, but exceeding 230°C risks material scorching. Future experiments should log systematic gradients for a comprehensive parameter map.

- Defect Mitigation: Success here stemmed from thorough drying and speed fine-tuning. Short shots can be countered by adding hold pressure (manual extension on this machine).