Modeling and Casting

This week focused on learning the fundamentals of modeling and casting techniques, with an emphasis on hands-on experimentation using silicone rubber and AB epoxy resin.

1.Materials familerization - as group assignment

As part of the group assignment, we explored the properties and handling techniques of commonly used materials in casting and model-making. The focus was on HongYeJie Silicone HY-630 and AB epoxy resin, both of which were used in hands-on experiments.

HongYeJie Silicone Rubber (HY-630)

· Type: Condensation-cure silicone rubber · Form: Two-component system (Part A: Base Silicone, Part B: Curing Agent) · Key Properties: ○ Medium hardness (Shore A ~30) with good flexibility ○ Excellent tear resistance and durability ○ High detail reproduction for mold applications ○ Suitable for both manual pouring and brush-on applications · Applications: ○ Mold making for resin, plaster, cement, wax, and low-temperature alloy casting ○ Prototyping and artistic reproduction (e.g., figurines, decorative items) · Mixing Ratio: 100:3 (by weight) · Curing Time: 3–6 hours at room temperature (faster with heat) · Special Notes: ○ Degassing is recommended for bubble-free molds ○ Compatible with a range of release agents for clean demolding

AB Epoxy Resin

· Type: Two-part thermosetting epoxy system · Form: Liquid before curing (Part A: Resin, Part B: Hardener) · Key Properties: ○ High transparency (can be pigmented as needed) ○ Strong adhesion and surface finish ○ Low shrinkage and good dimensional stability · Applications: ○ Small cast items such as keychains, charms, buttons, or enclosures ○ Decorative inlays and bonding layers · Mixing Ratio: Typically 1:1 or 2:1 (by volume) depending on supplier · Curing Time: 12–48 hours at room temperature (accelerated by gentle heating)

Safety and Handling Guidelines

· Always wear gloves, safety goggles, and work in a well-ventilated area · Carefully follow mixing ratios and stirring procedures to ensure consistent curing · Store both silicone and resin components in sealed containers away from moisture and direct sunlight

This material study provided our group with a practical foundation for casting workflows and deepened our understanding of mold-making processes with professional-grade silicone and resin systems.

2.Creating a Duck-Shaped Charm Using Silicone Molding and AB Epoxy Resin

This process outlines the steps to duplicate a duck-shaped charm using silicone rubber mold making and transparent AB epoxy resin casting. The original duck charm is used as the master model.

Materials & Tools

· Duck-shaped original charm (master model) · HongYeJie Silicone HY-630 (or other mold-grade silicone) · AB epoxy resin (transparent) · Mixing cups and stir sticks · Digital scale · Gloves and protective equipment · Plastic or acrylic container (for mold box) · Release agent (optional but recommended) · Hot glue gun or adhesive putty (to fix model in place)

Part 1: Creating the Silicone Mold

Prepare the Mold Box

· Choose a plastic container slightly larger than the duck charm.

Mix Silicone (HY-630)

· Mix Part A and Part B of the silicone rubber in a 100:3 weight ratio.

· Stir thoroughly and slowly to minimize air bubbles.

· Stir thoroughly and slowly to minimize air bubbles.  · Optional: Vacuum degas to remove bubbles for high detail.

· Optional: Vacuum degas to remove bubbles for high detail.

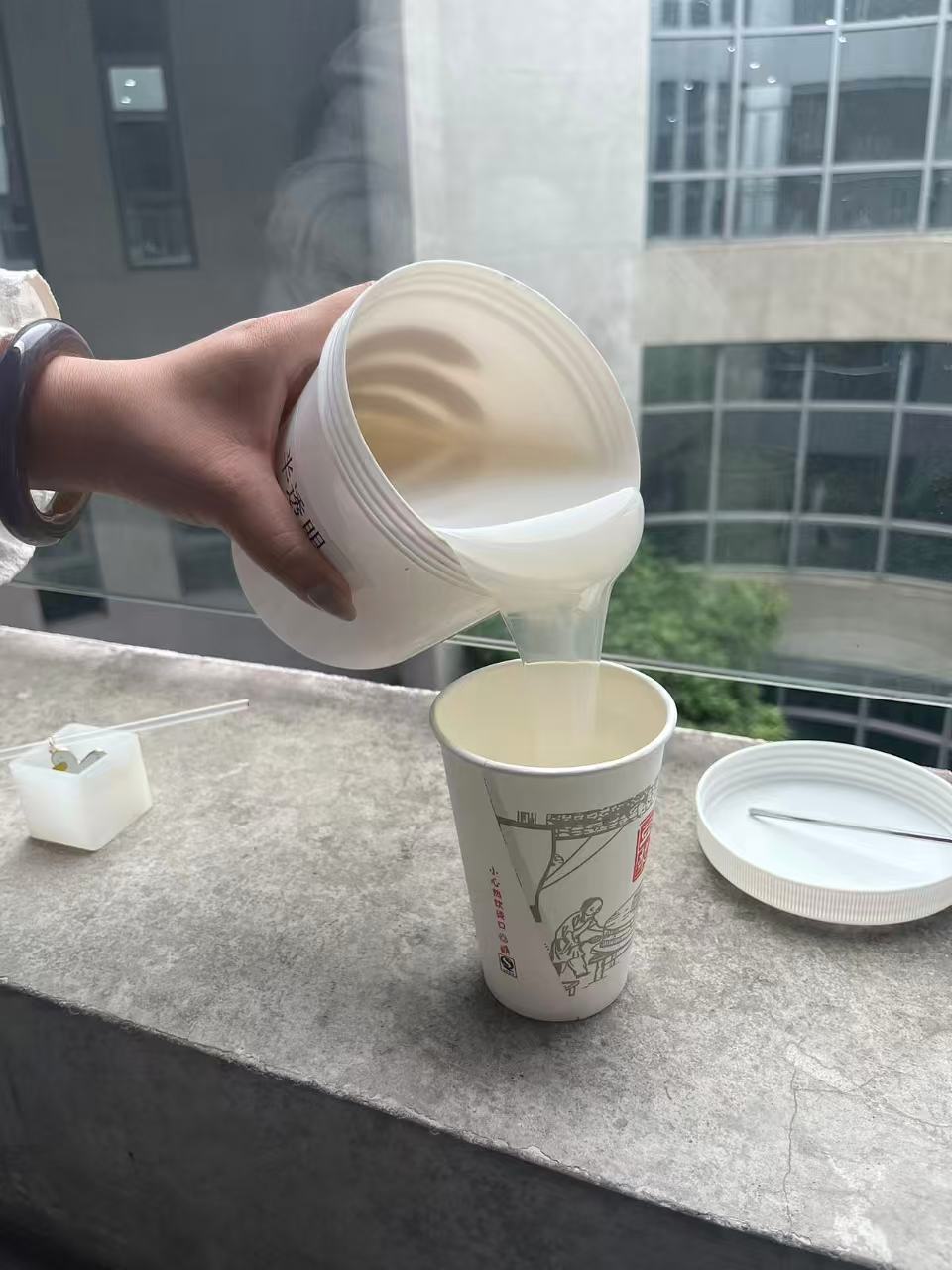

Pour Silicone Over Model

· Slowly pour silicone from one corner, allowing it to rise and cover the entire model. · Tap the container gently to help bubbles rise.

· Let the silicone cure at room temperature for 4–6 hours, or as recommended.

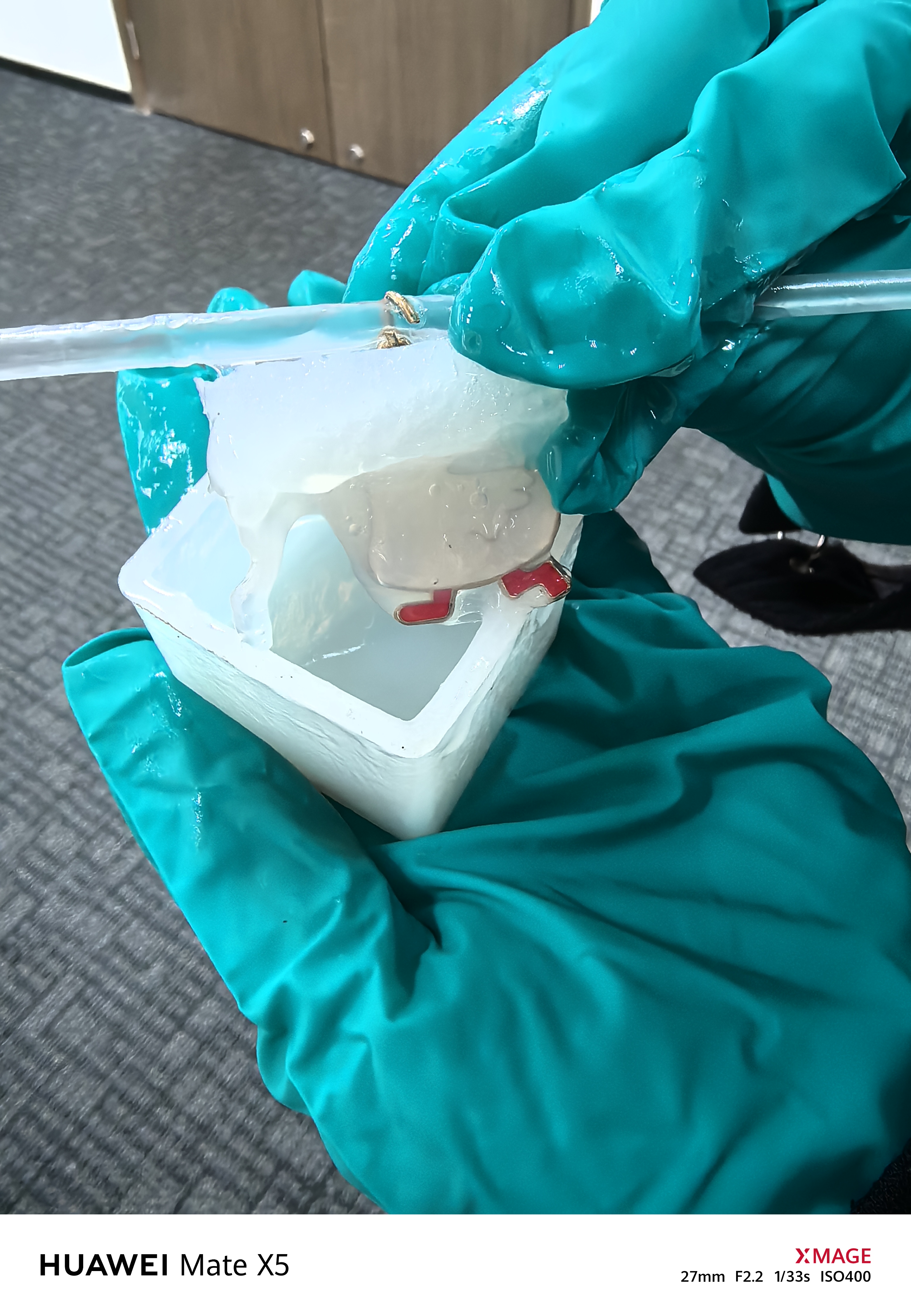

Demold

· Once cured, remove the mold from the container. · Carefully pull out the original duck charm. You now have a reusable silicone mold. Unfortunately, our proportioning failed and the silicone couldn't solidify completely.

Part 2: Casting the Transparent Duck with AB Epoxy Resin

Prepare the Epoxy Resin

· Mix Part A (resin) and Part B (hardener) according to the product’s specified ratio (commonly 1:1 or 2:1 by volume). · Stir slowly and evenly to avoid bubbles.

Pour Resin into the Mold · Carefully fill the duck-shaped silicone mold with the mixed epoxy.