Appearance

Lase cutting

1. Introduction

Laser cutting is a technology that uses a laser to cut or engraving materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

2. Modelling

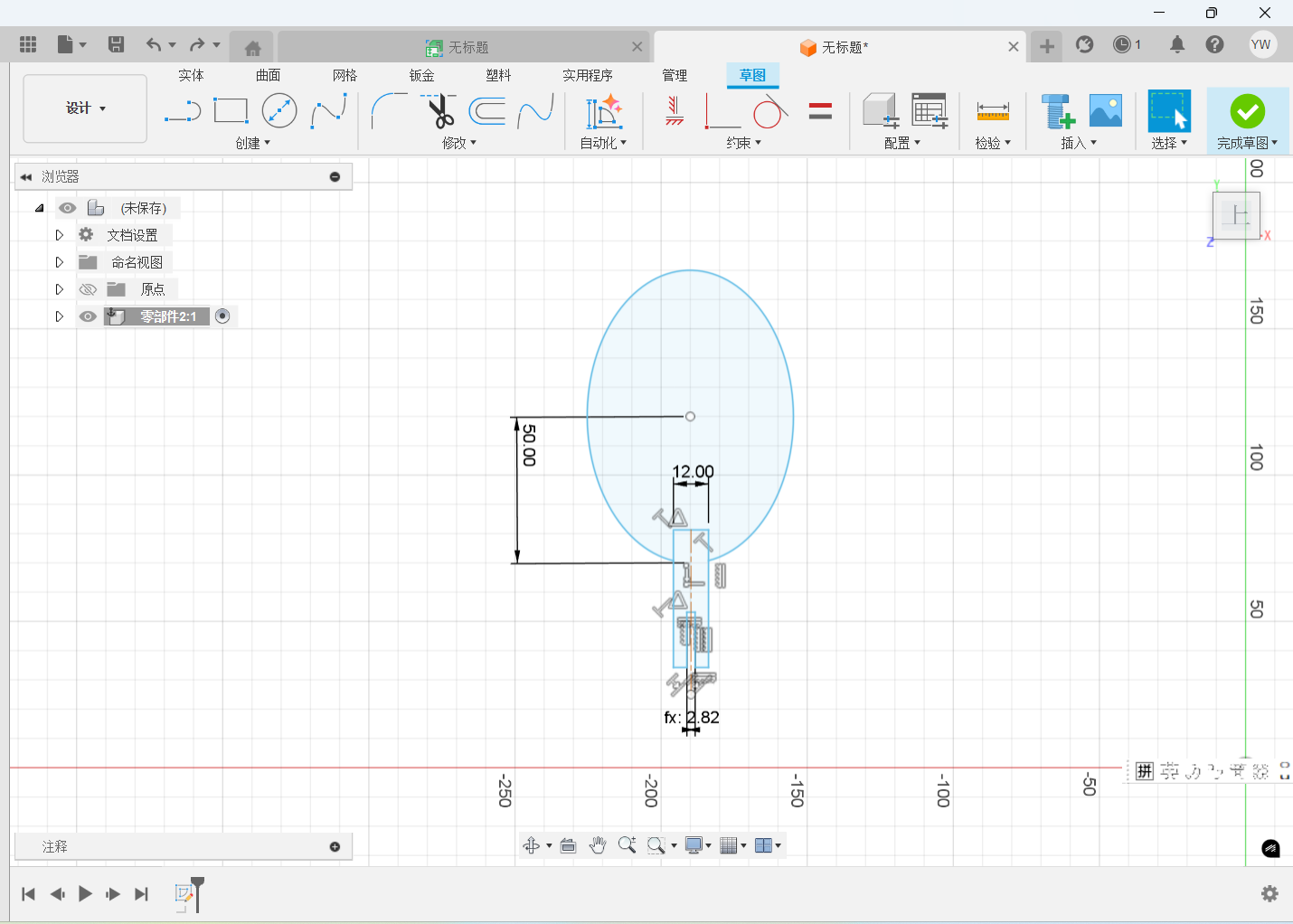

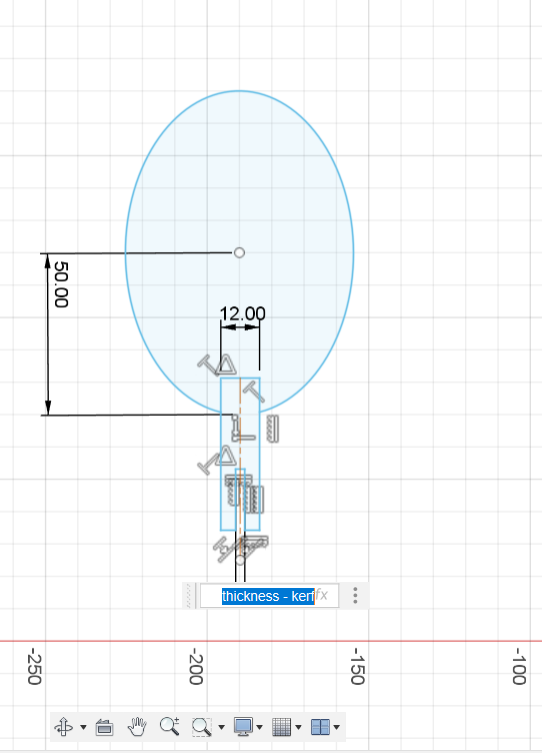

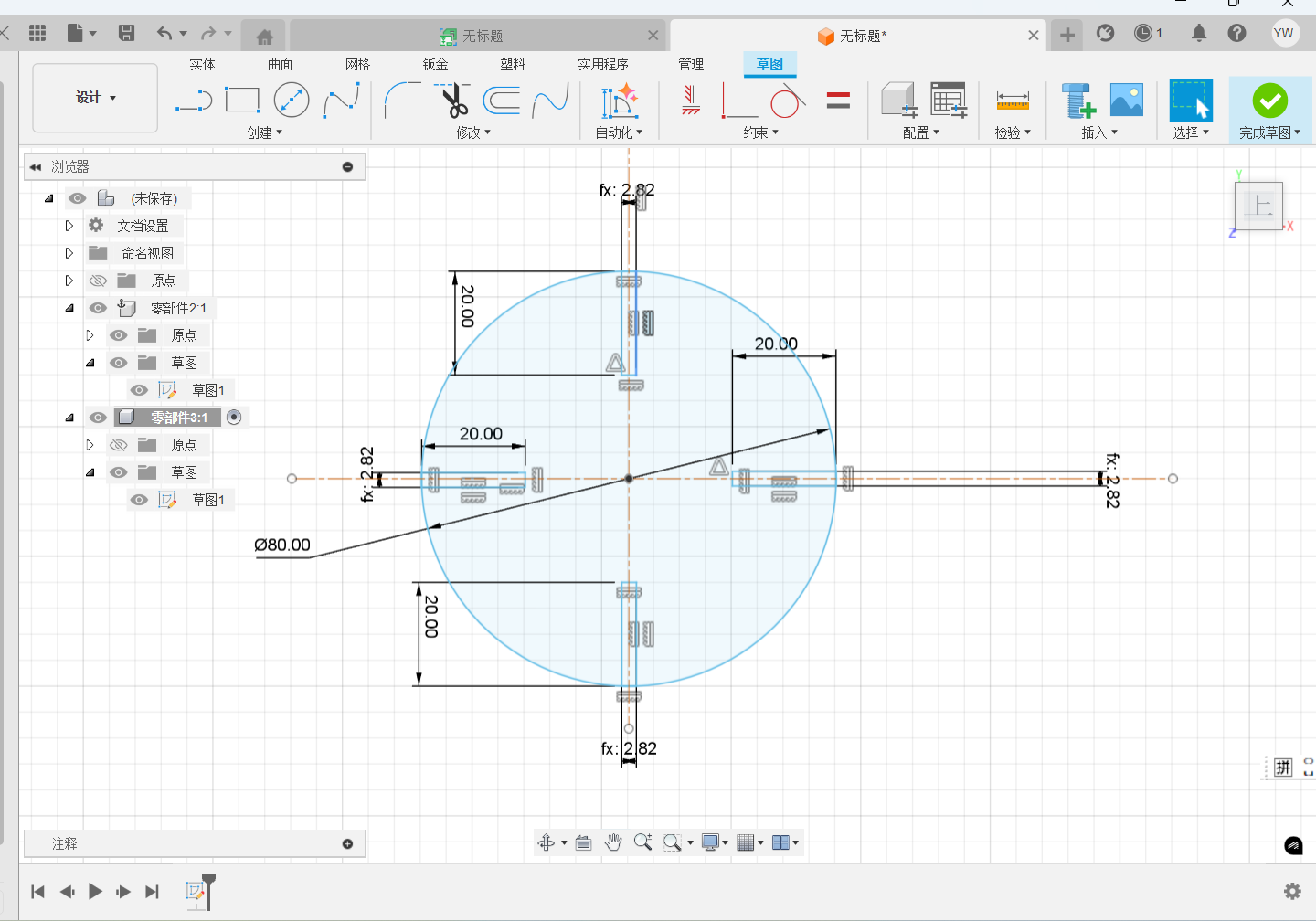

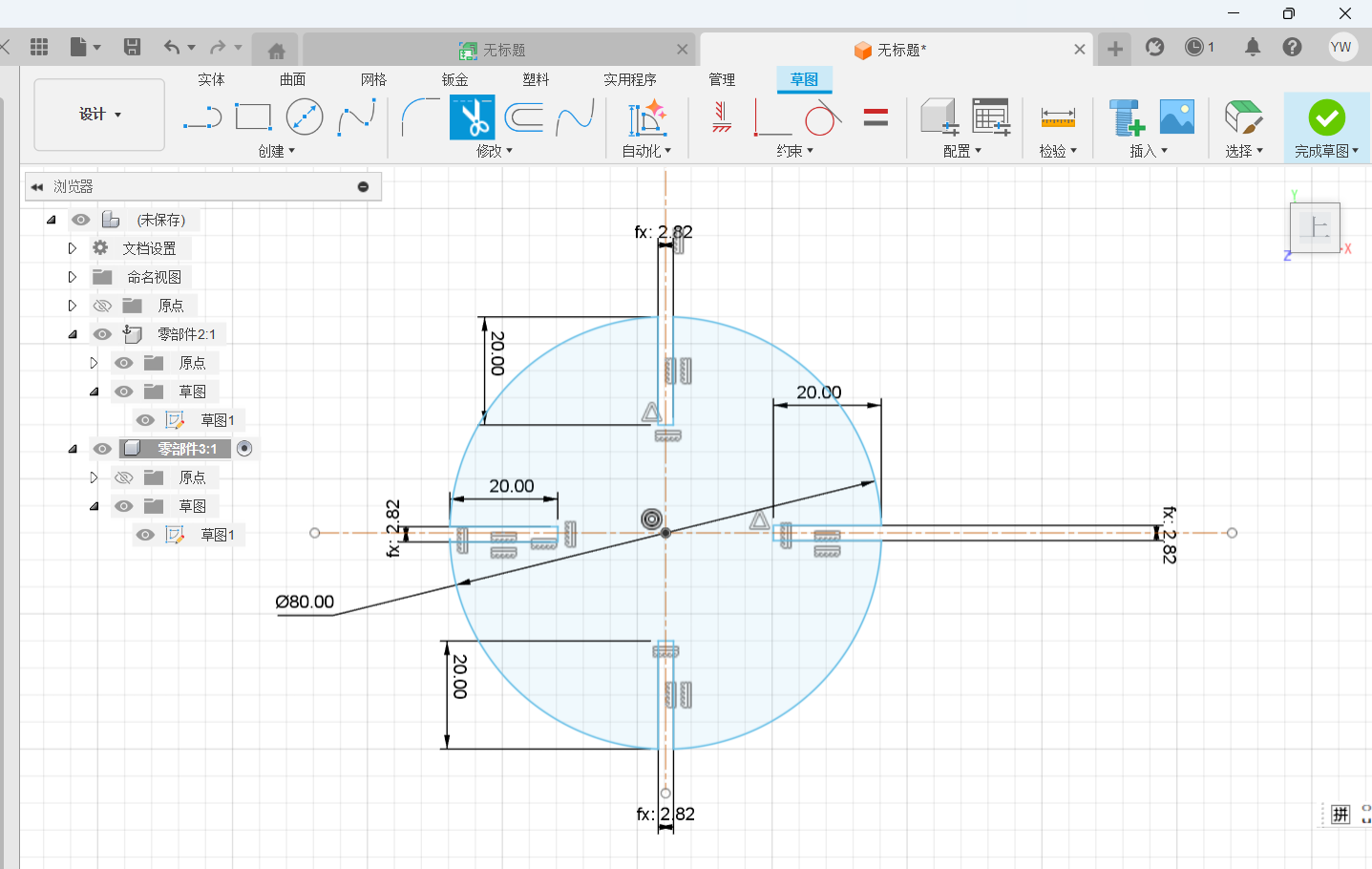

Firtsly, use Fusion to creat a 2D pattern. Keep the postion to inser the other part.

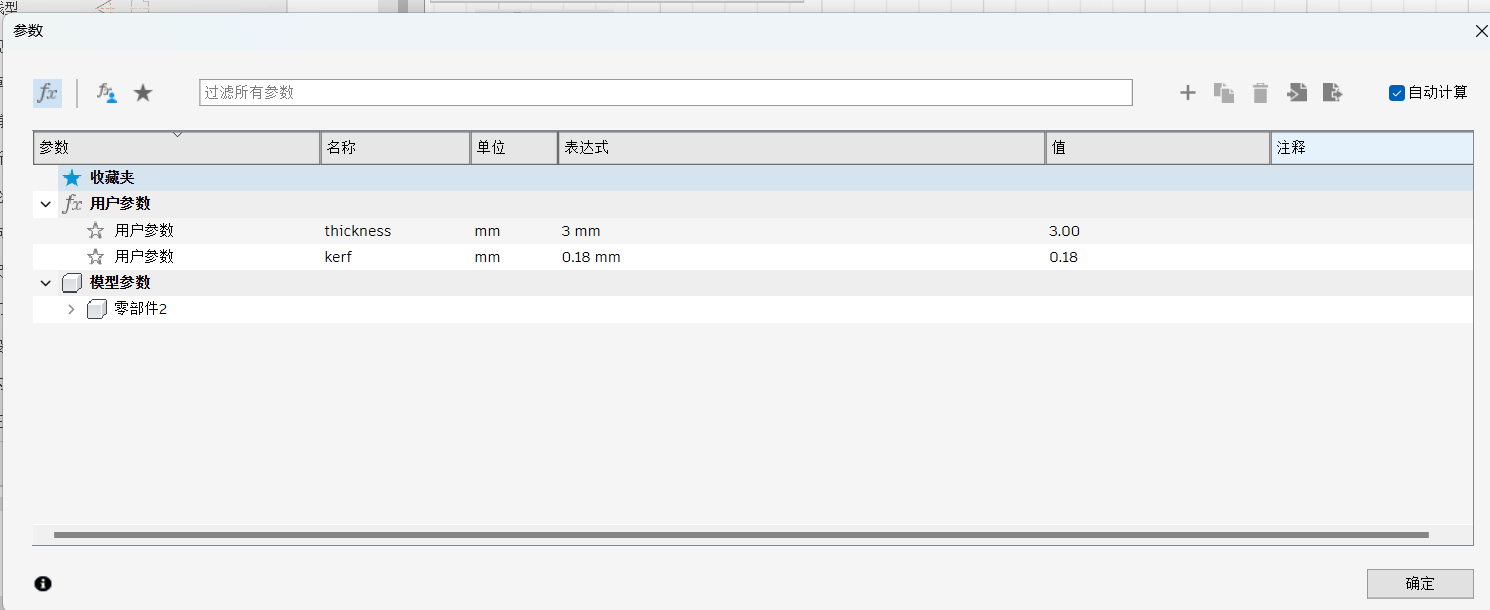

Use the parameter modelling to define the size of the insert position. To make the part insted to the another part reasonably. The size is defined by the thickness of the board minus the diamater of laser (kerf).

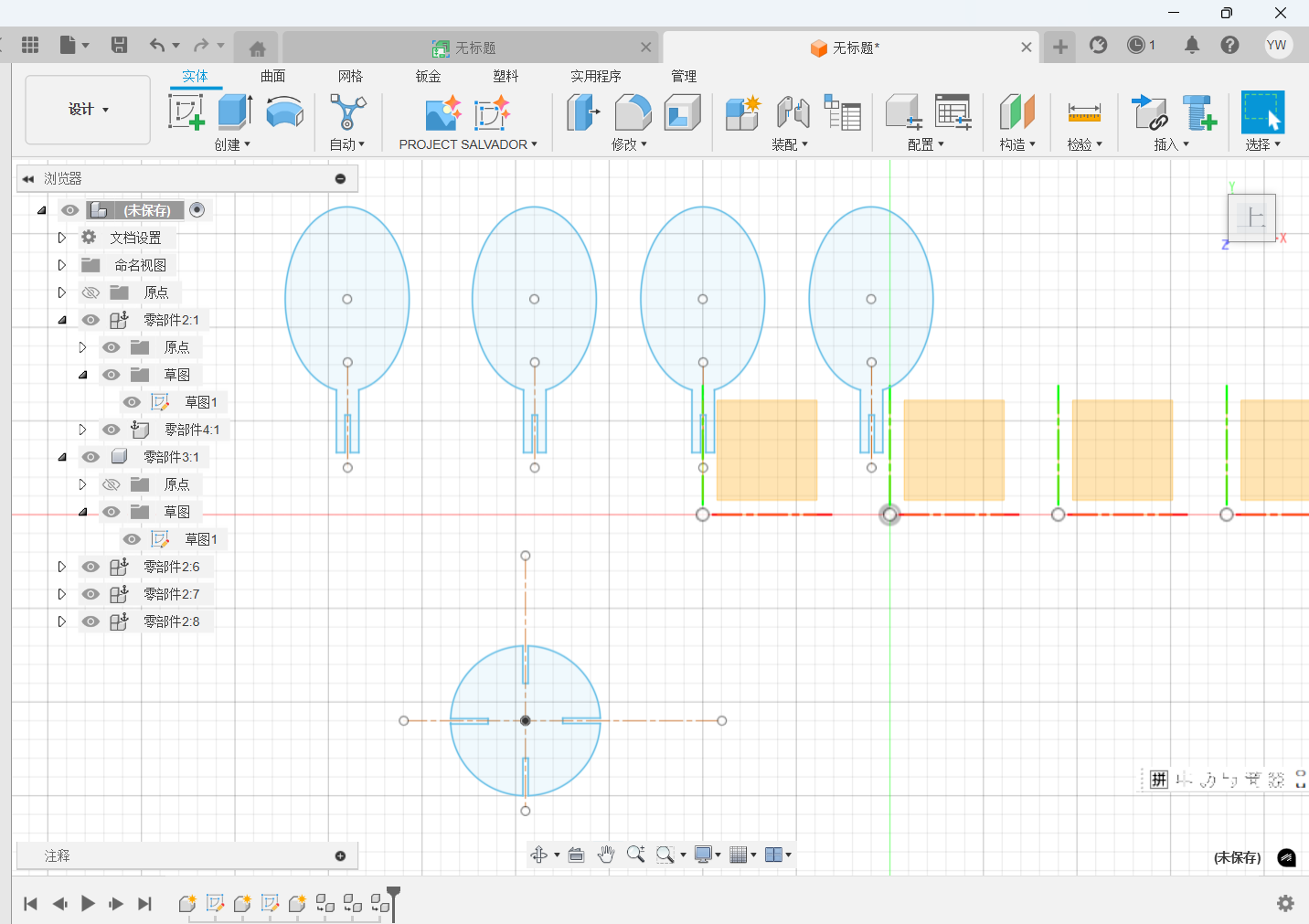

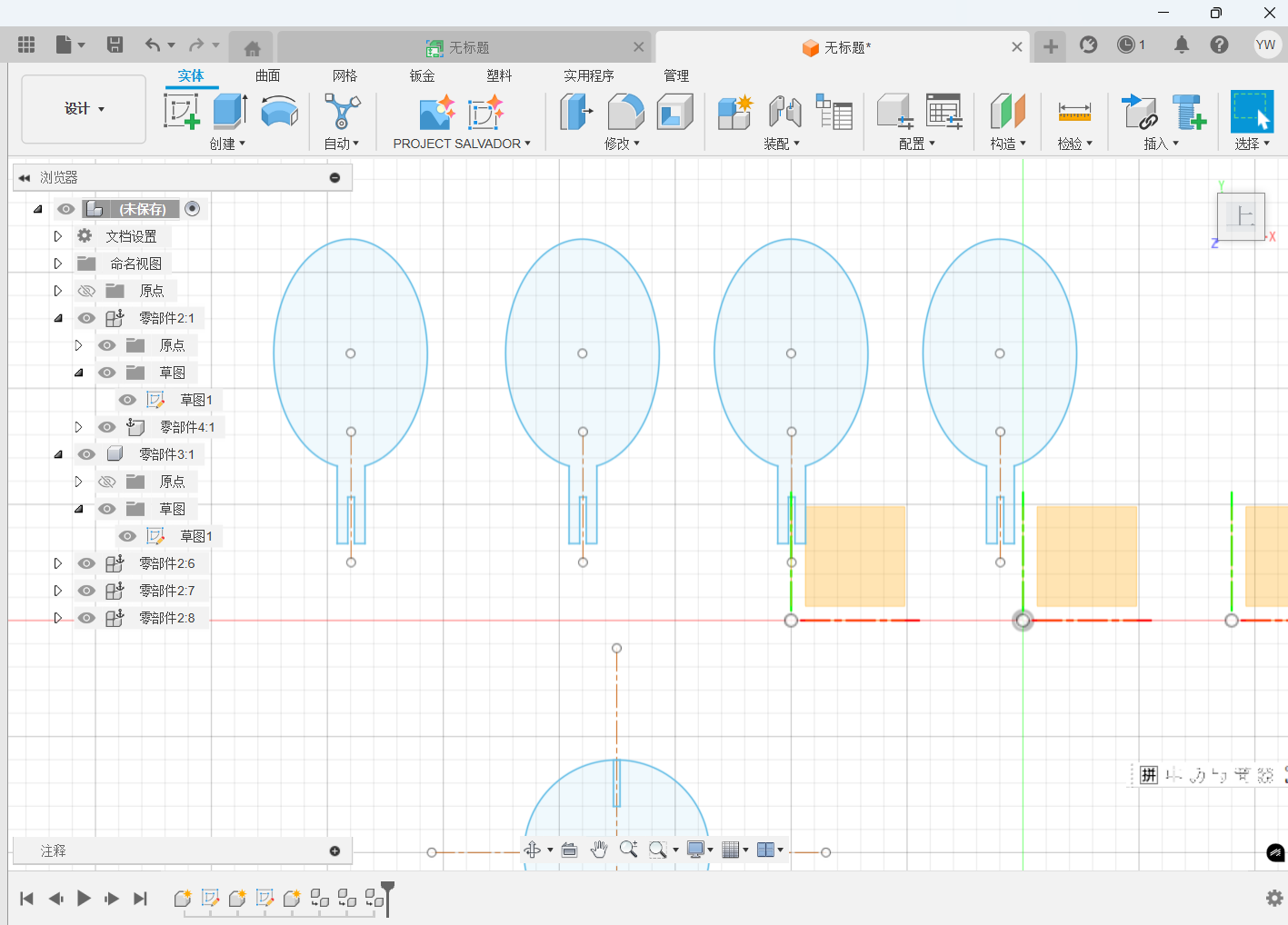

Secondly, copy the pattern.

Thridly, creat a model with four symmery insert positions.

Set the size correctly by setting parameter.

Finally, all the parts are modelled.