Electronics Production: PCB Milling

1. Core Machine Analysis

1.1 The Machine: Roland SRM-20

The Roland SRM-20 is a compact desktop CNC milling machine specifically designed for offices, laboratories, and educational environments. It is the standard equipment in FabLabs for fabricating high-precision Printed Circuit Boards (PCBs).

- Process Type: Subtractive Manufacturing. Unlike 3D printing (additive), it removes material from a solid block. In PCB production, it mills away the excess copper layer to isolate conductive traces.

- Key Specifications:

- Work Area: 203.2 (X) x 152.4 (Y) x 60.5 (Z) mm.

- Spindle Speed: Up to 7000 RPM, ideal for fine detail work.

- Resolution: 0.01 mm / step (mechanical resolution), ensuring precision for Surface Mount Device (SMD) components.

- Design Features:

- Full Enclosure: Prevents dust from spreading and reduces noise, ensuring safety.

- Dust Collection: A slide-out tray at the bottom collects copper and substrate debris for easy cleaning.

1.2 The Software: VPanel for SRM-20

VPanel is the dedicated control software for the SRM-20. It acts as the "cockpit" between your computer and the machine. It does not generate toolpaths (CAM software does that); it only executes them.

- Coordinate Systems:

- Machine Coordinates: The absolute, fixed position of the machine spindle (cannot be changed).

- User Coordinates: The most important system! We use "Set Origin" to define the starting point (X/Y/Z Zero) for our specific job.

- Key Functions:

- Move: Controls the spindle movement along X, Y, and Z axes (supports continuous or step movement).

- Set Origin:

- XY Origin: Defines the bottom-left corner of your PCB design on the material.

- Z Origin (Critical!): Defines the exact height of the tool tip relative to the material surface. Setting this too low breaks the bit; too high results in no cut.

- Override: Adjusts spindle speed and feed rate percentages in real-time during operation to fine-tune cutting quality.

2. Market Landscape: Comparable Devices

Besides the Roland SRM-20, there are several other common desktop CNC machines used for PCB production.

2.1 Bantam Tools (Othermill)

- Origin: USA.

- Features: Excellent software experience with automatic conductive probing for material location and tool length detection.

- Pros: Faster than SRM-20, very easy tool changes, high software integration.

- Target: High-budget labs requiring premium user experience.

2.2 LPKF ProtoMat (Industrial Grade)

- Origin: Germany.

- Features: Industrial-grade PCB prototyping.

- Pros: Extremely high precision, chemical-free process, integrated vacuum, capable of through-hole plating for multilayer boards.

- Cons: Extremely expensive (5-10x the price of SRM-20), high maintenance.

2.3 Genmitsu 3018-PRO (Entry Level)

- Origin: China.

- Features: Open-source architecture (GRBL), extremely affordable.

- Cons: Poor rigidity, high spindle runout, difficult to mill fine traces (< 0.2mm), requires significant modification.

- Target: DIY hobbyists and makers on a strict budget.

3. Comparison Matrix

| Feature | Roland SRM-20 | Bantam Tools | Genmitsu 3018 |

|---|---|---|---|

| Price | Mid-Range ($$) | High ($$$) | Very Low ($) |

| Precision | High | Very High | Low/Mid |

| Ease of Use | Good | Excellent | Hard (Steep learning curve) |

| Software | VPanel (Simple Control) | Bantam SW (Full Feature) | Candle/GRBL (Open Source) |

| Target User | FabLabs / Schools | Pro Engineers | DIY Hobbyists |

Conclusion: The Roland SRM-20 is the standard for FabLabs globally due to its balance of stability, precision, and cost.

4. Operation Workflow

校准:

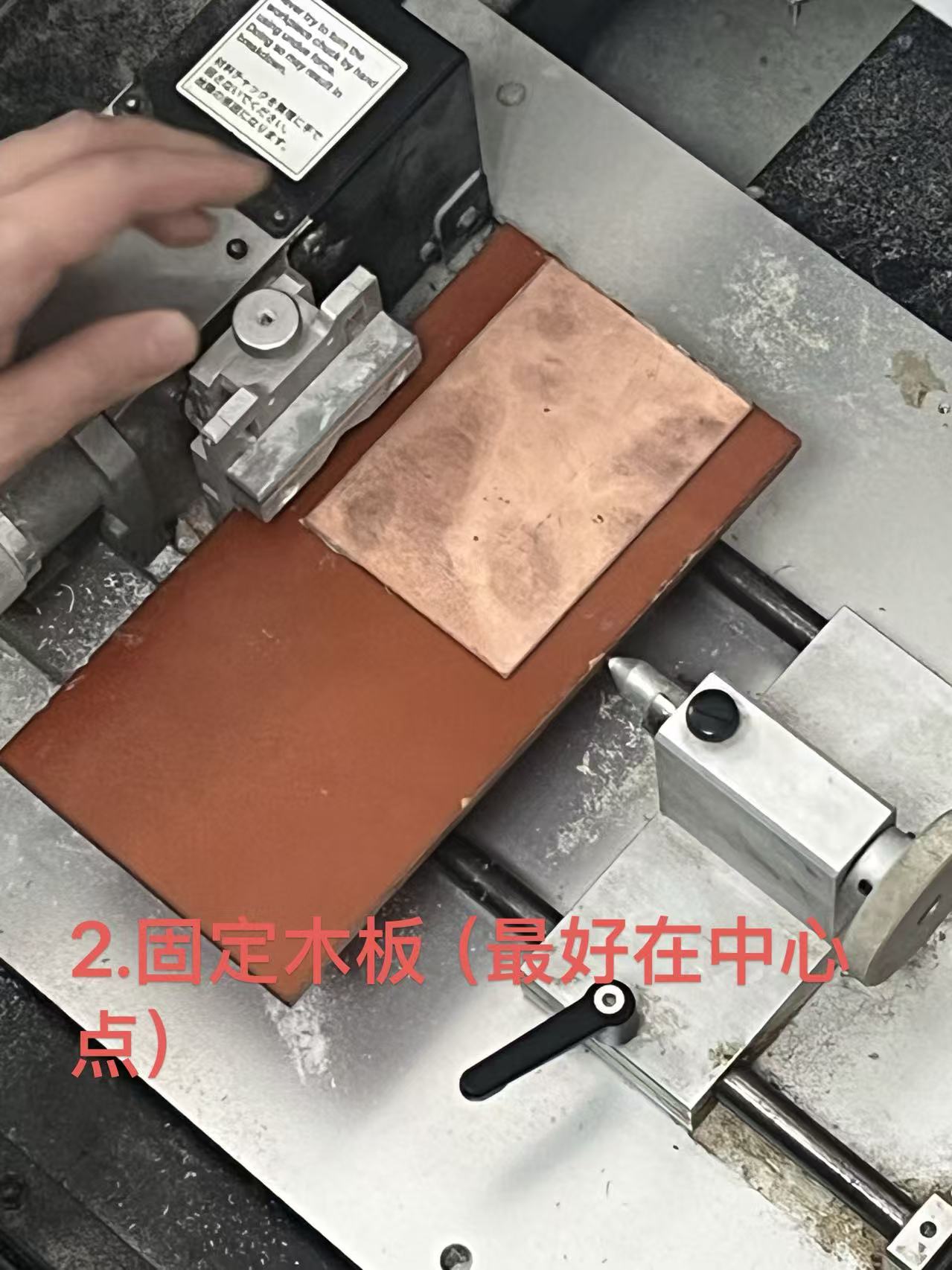

固定木板:

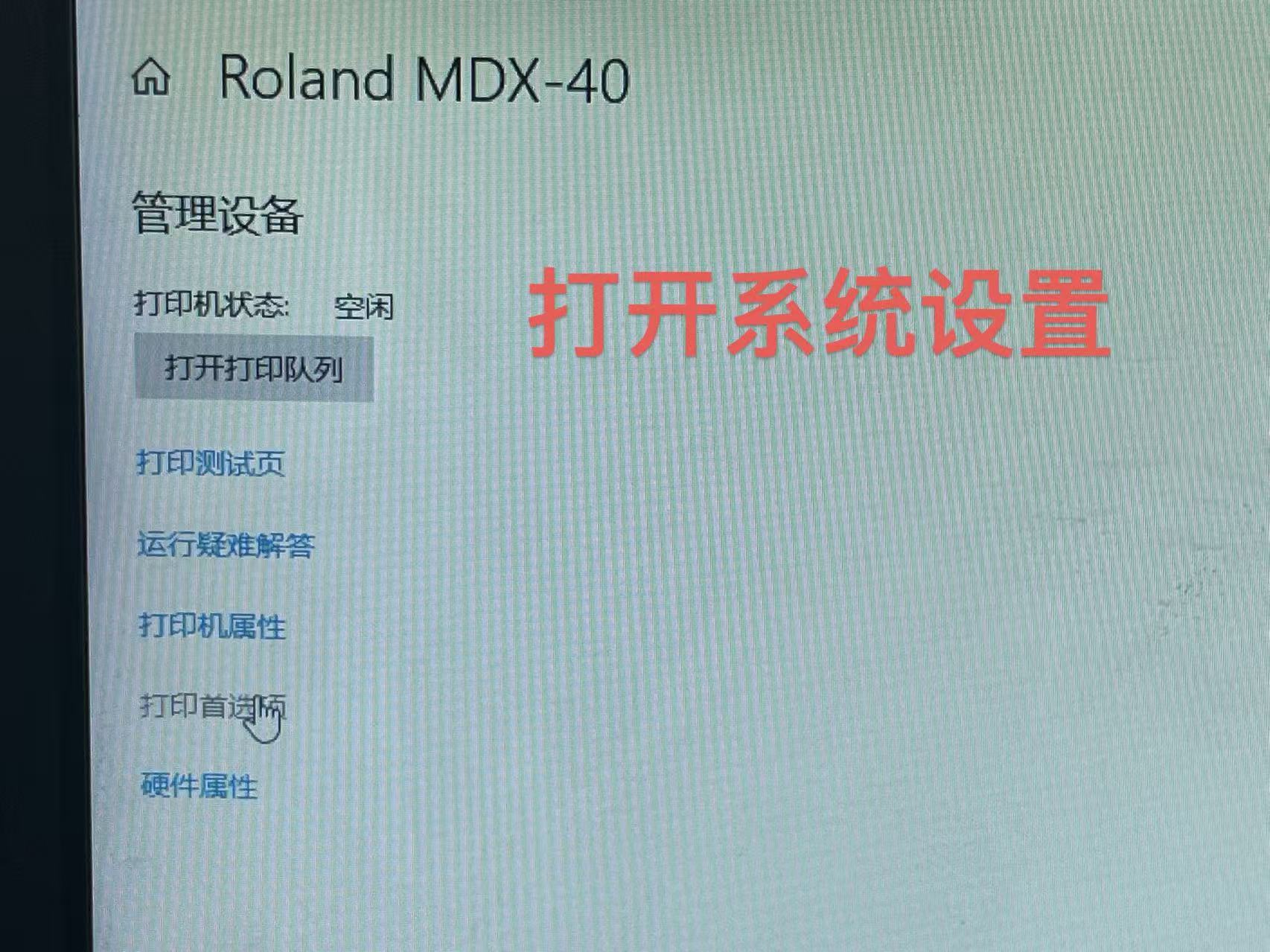

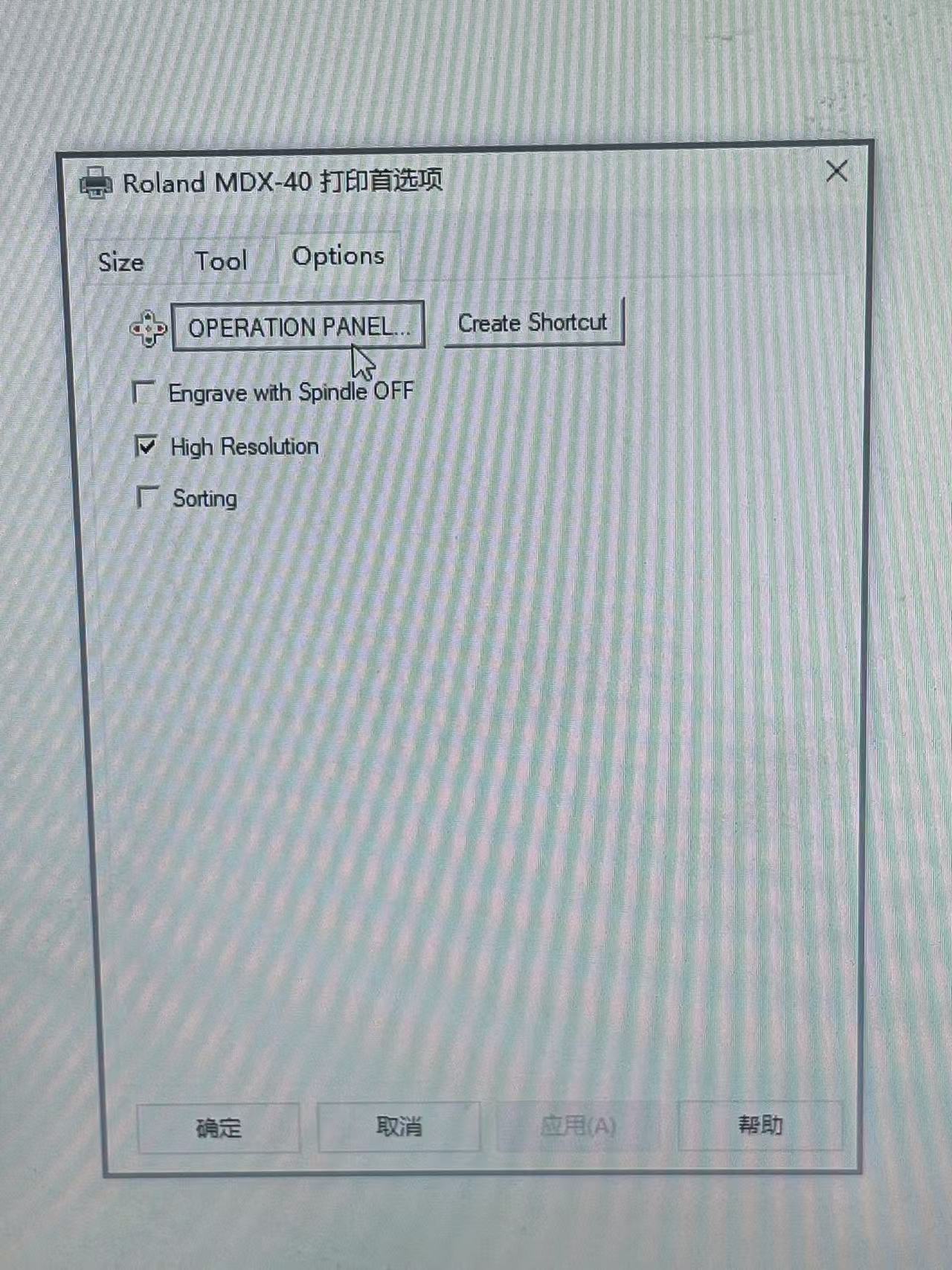

打开系统设置:

打开系统设置:

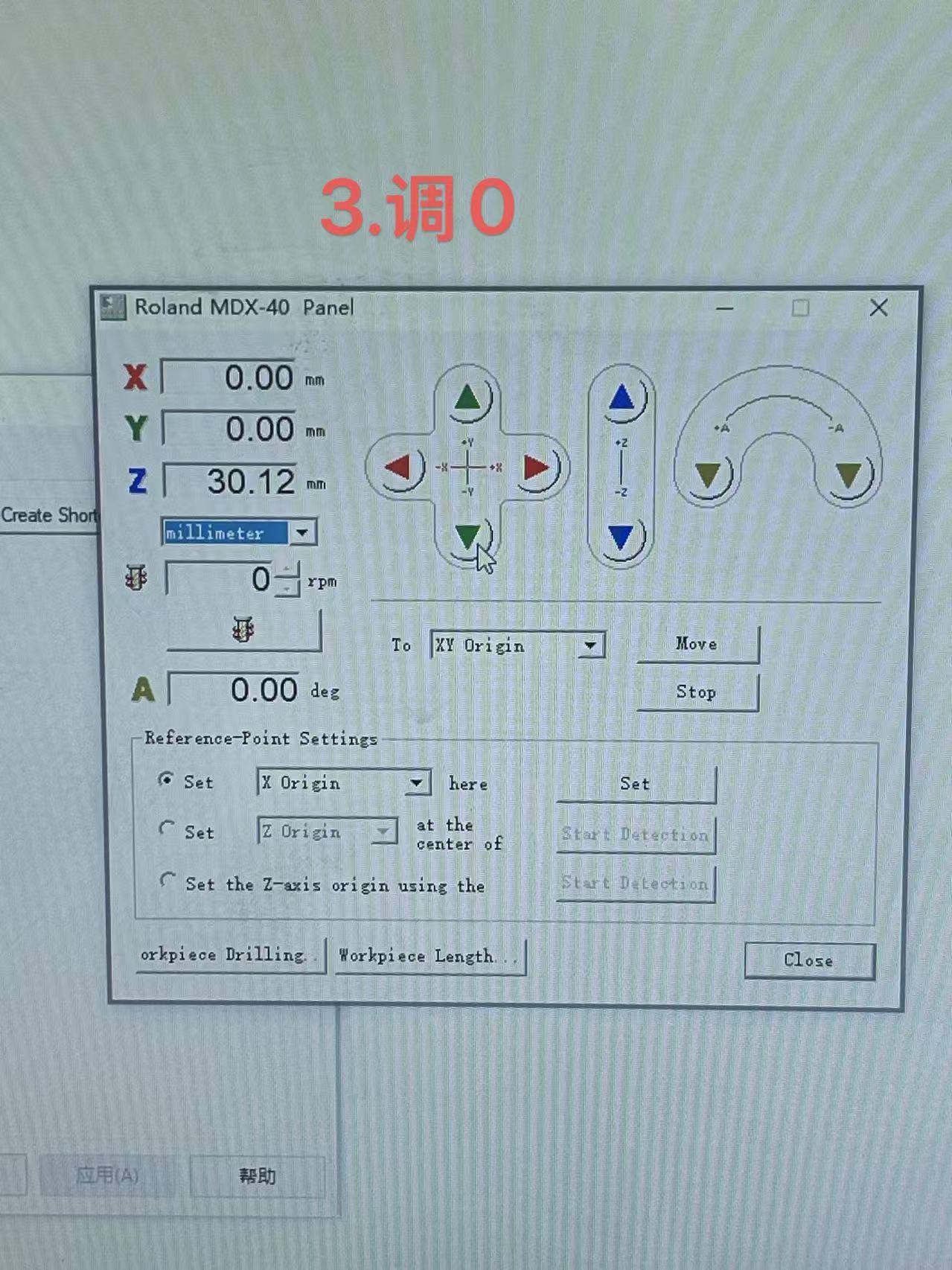

调0:

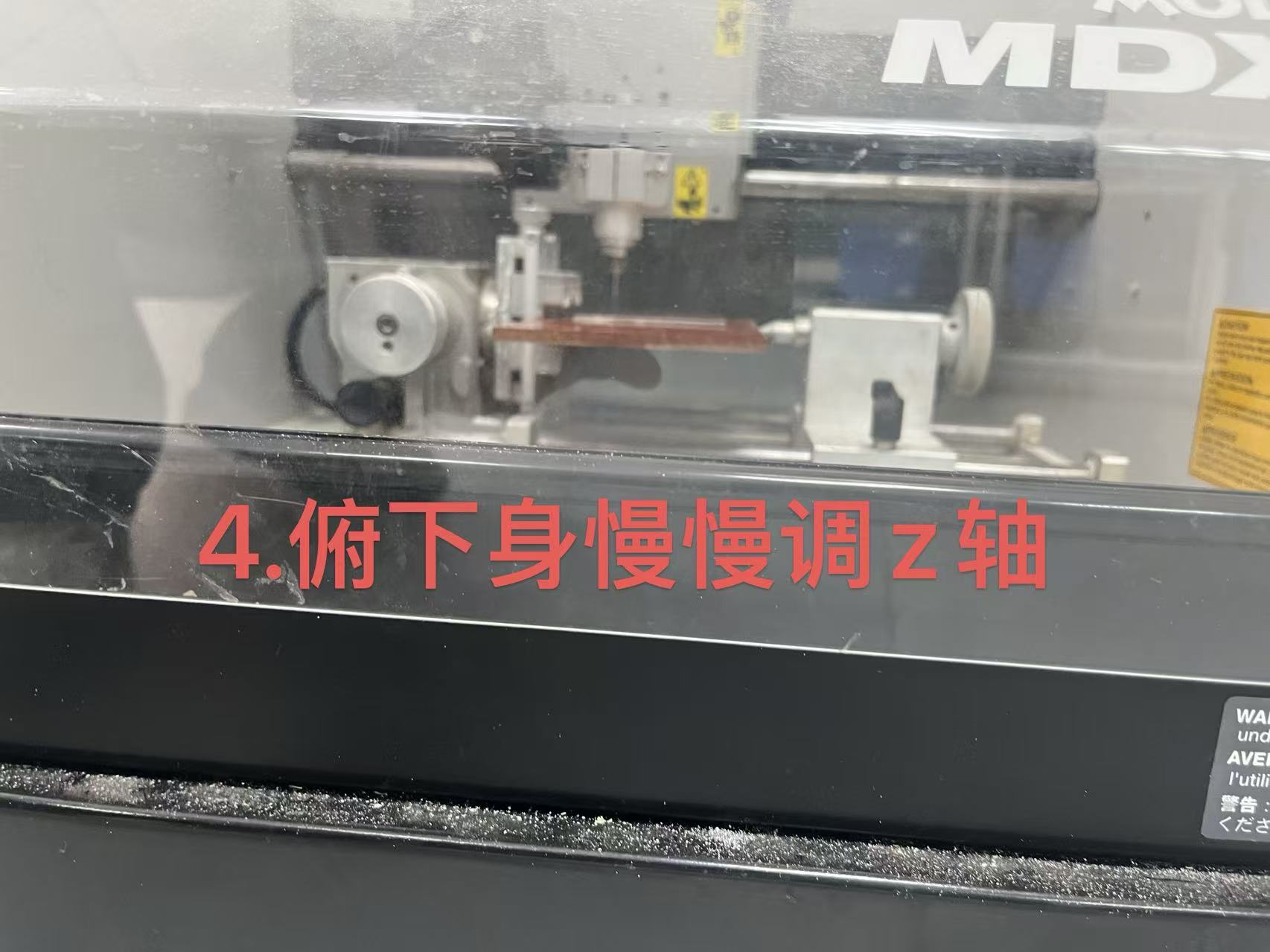

俯下身慢慢调Z轴:

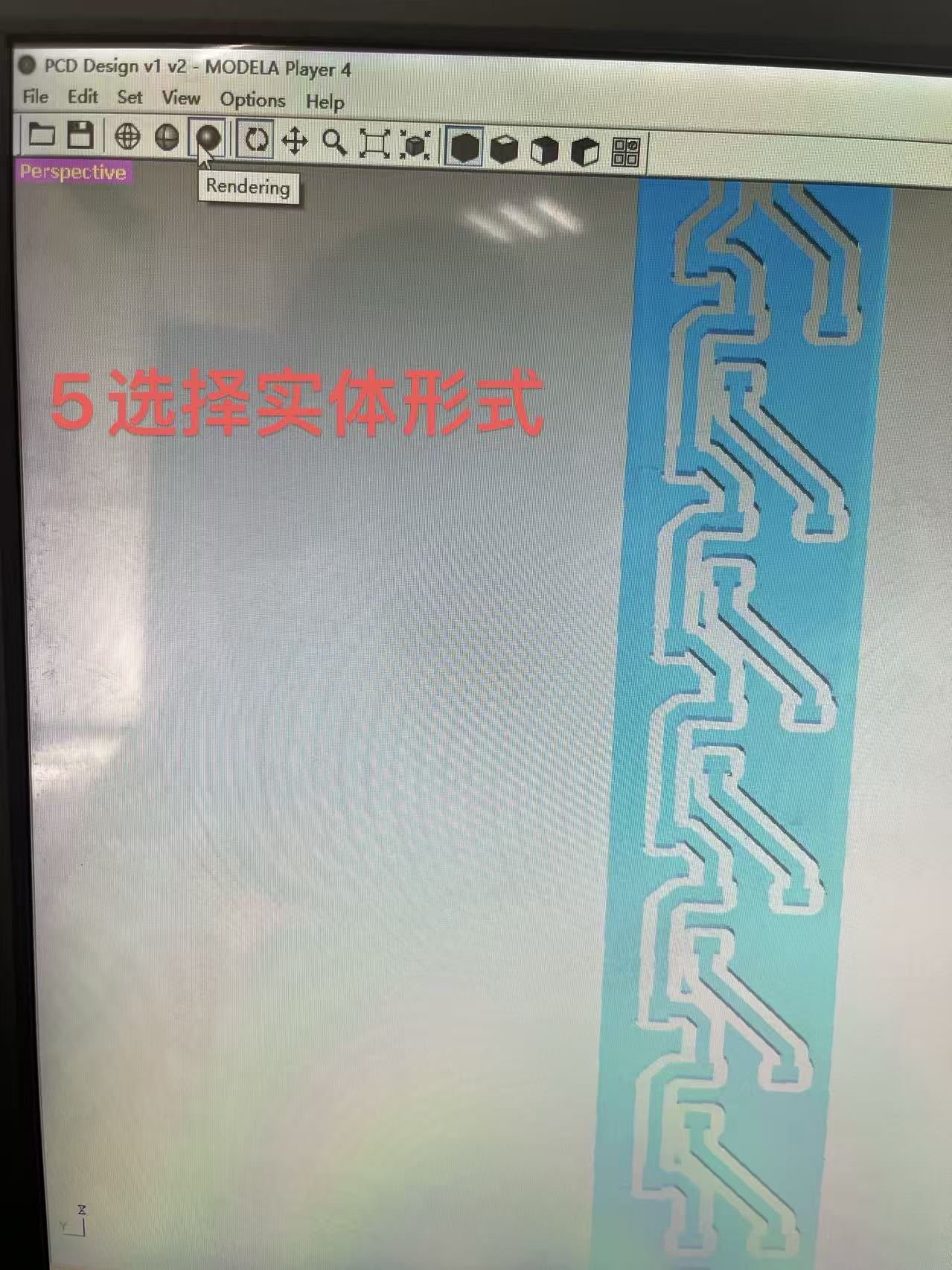

选择实体形式:

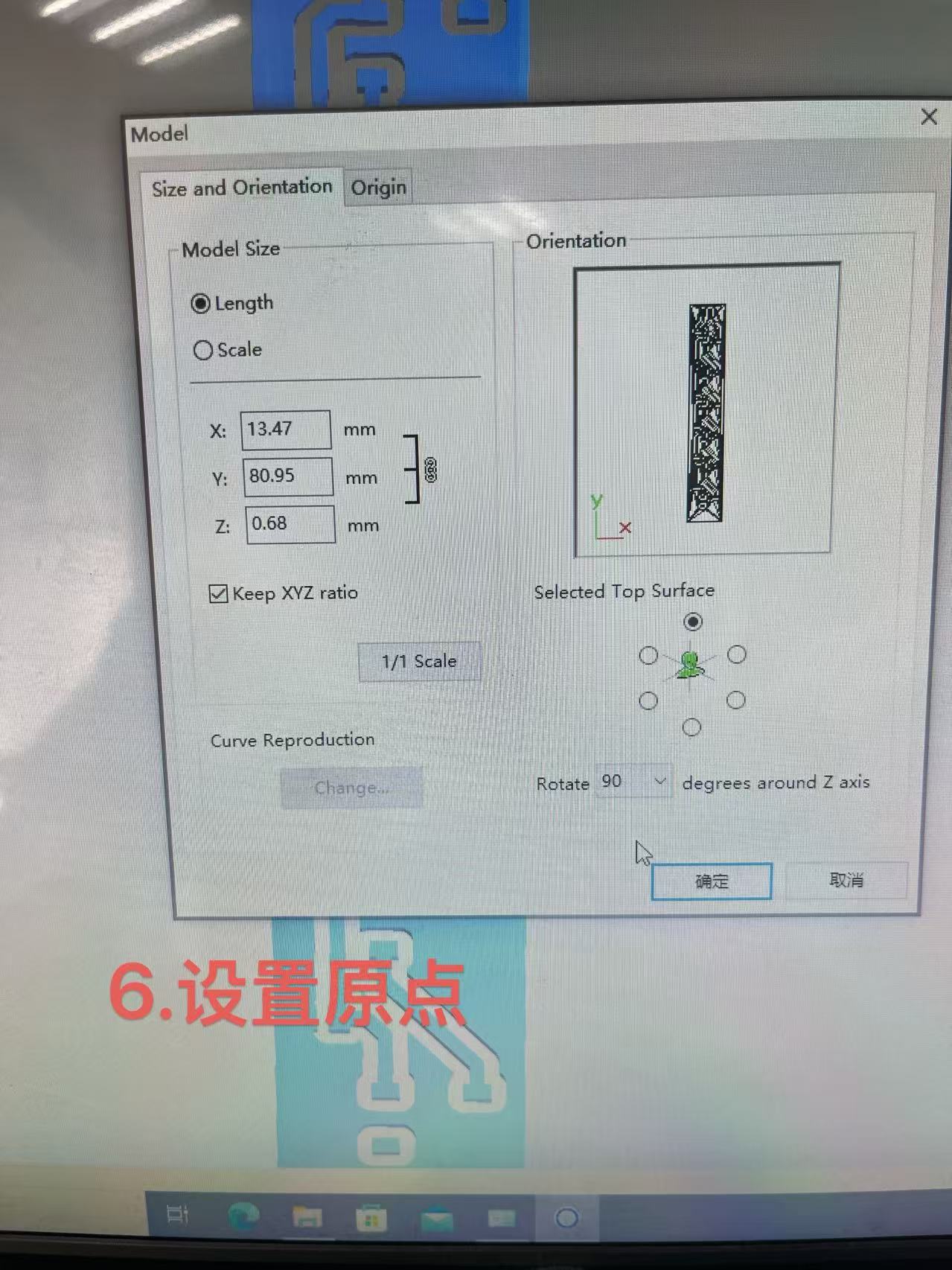

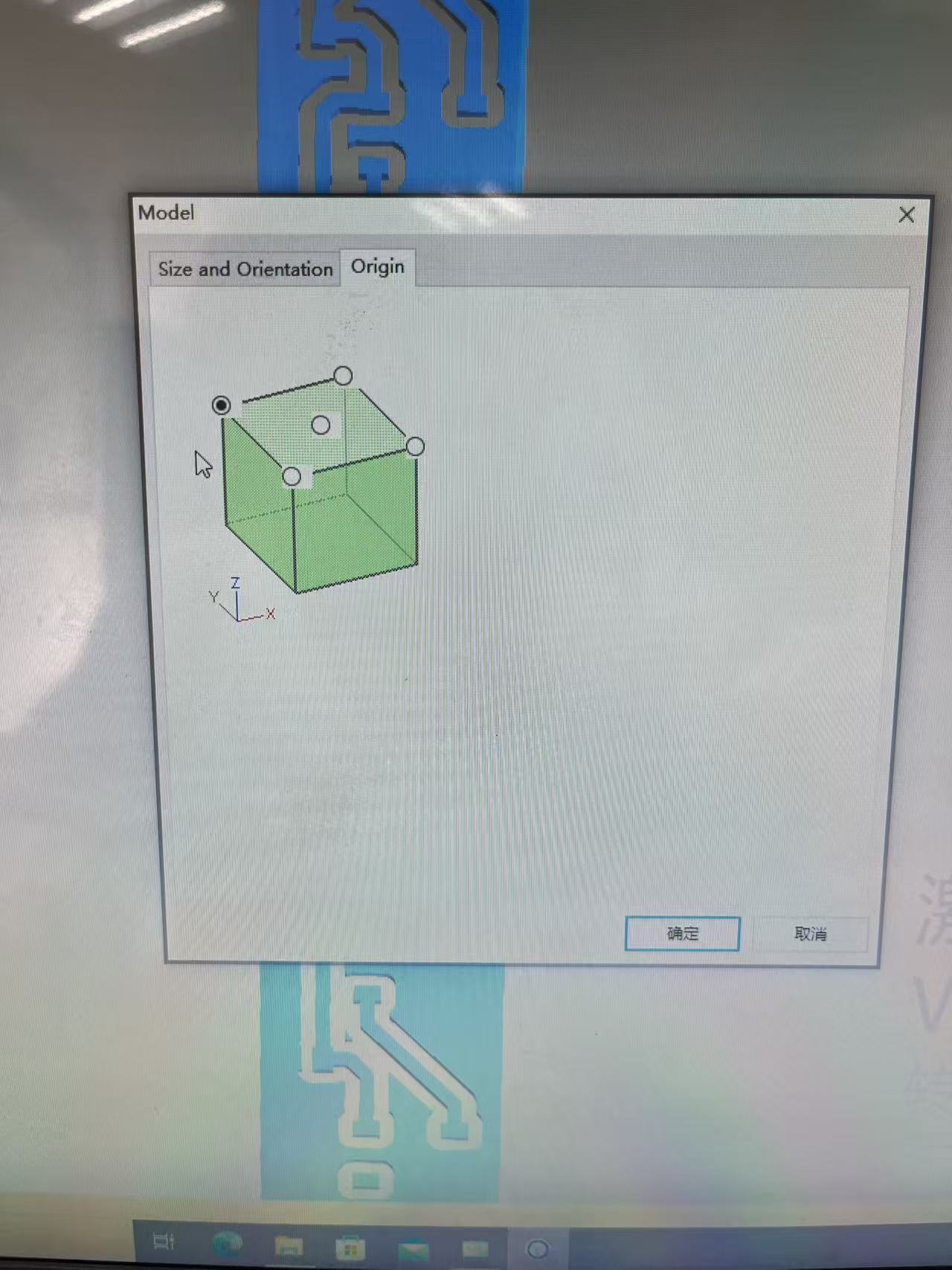

设置原点:

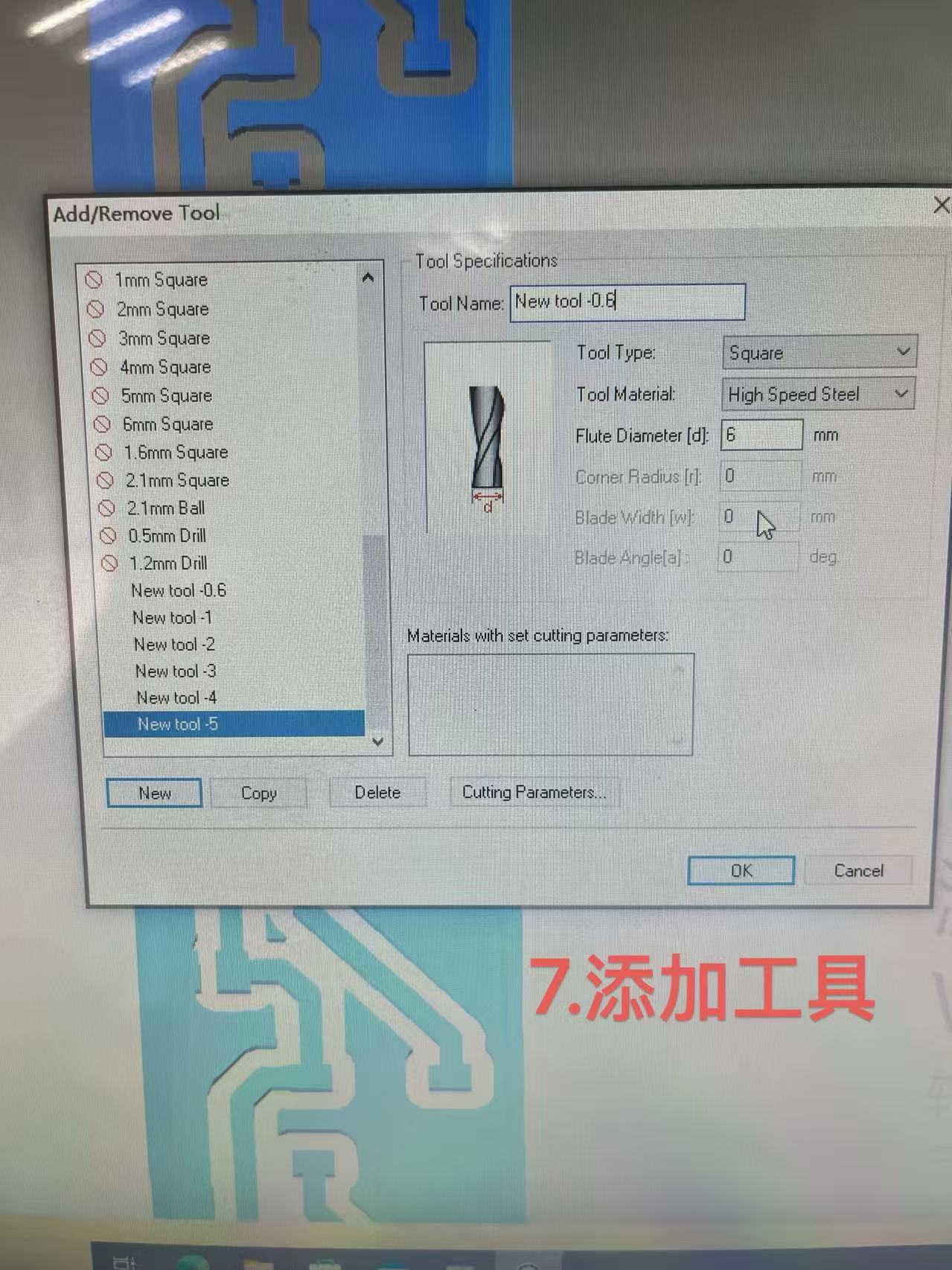

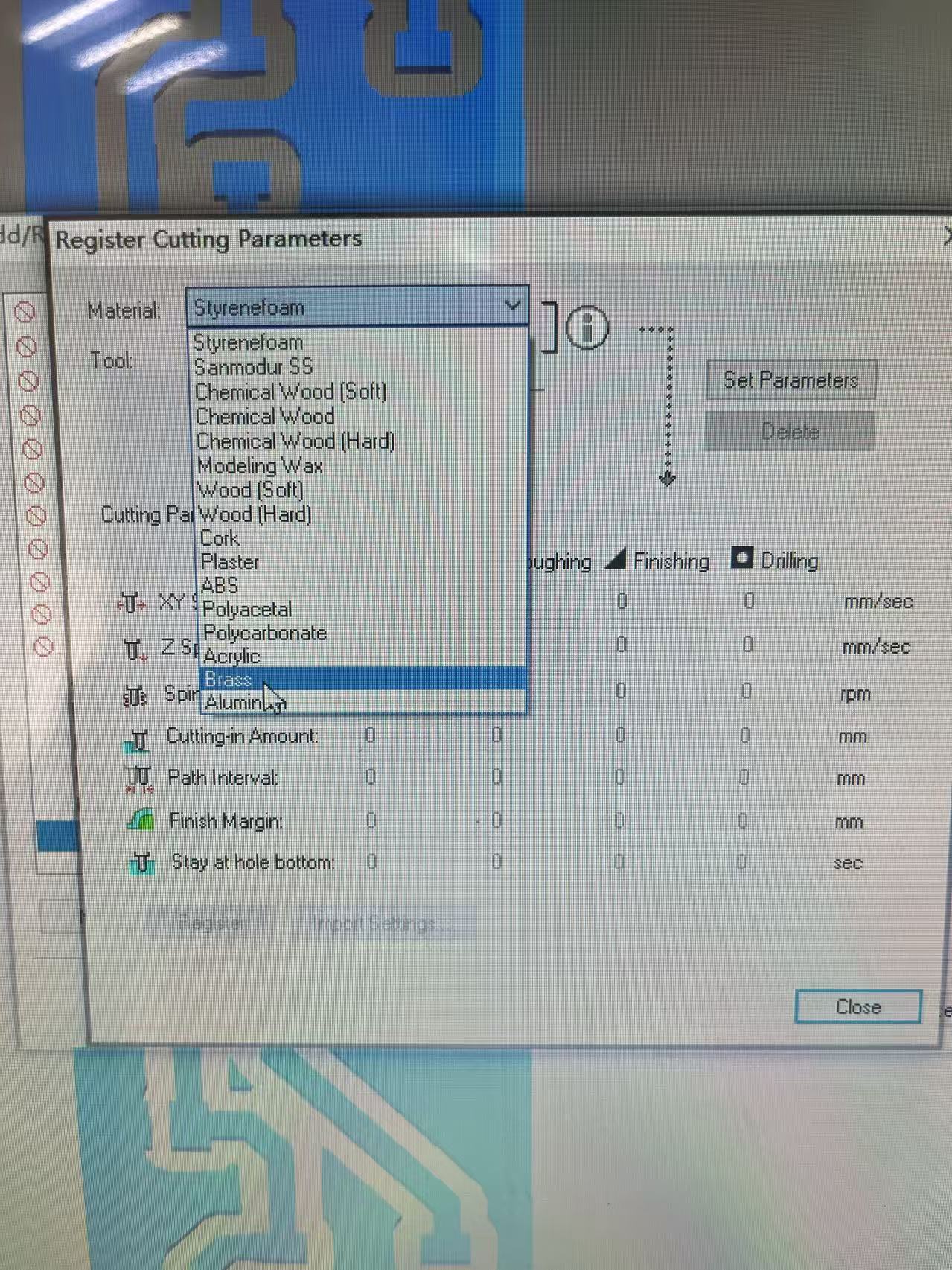

添加工具:

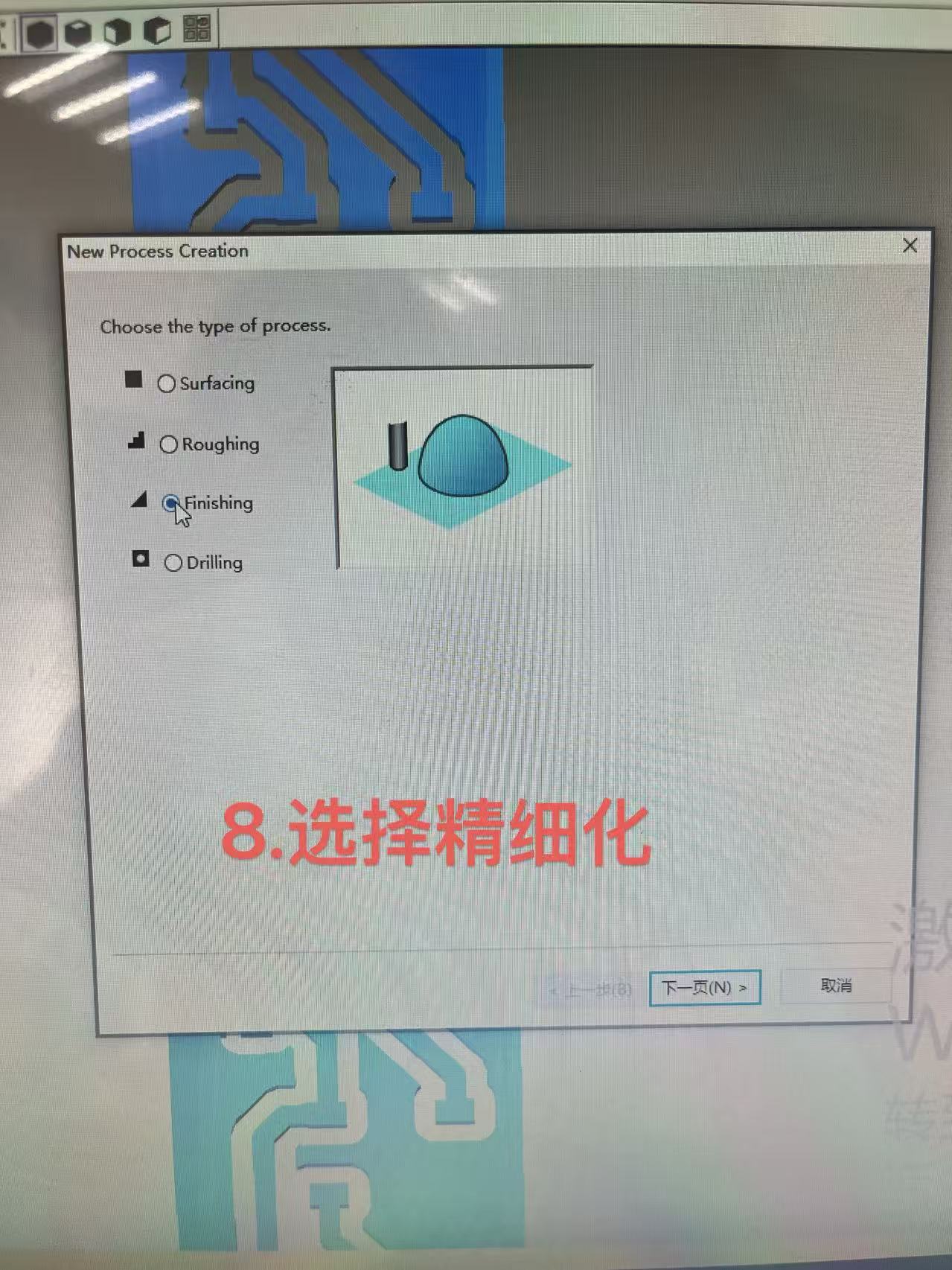

选择精细化:

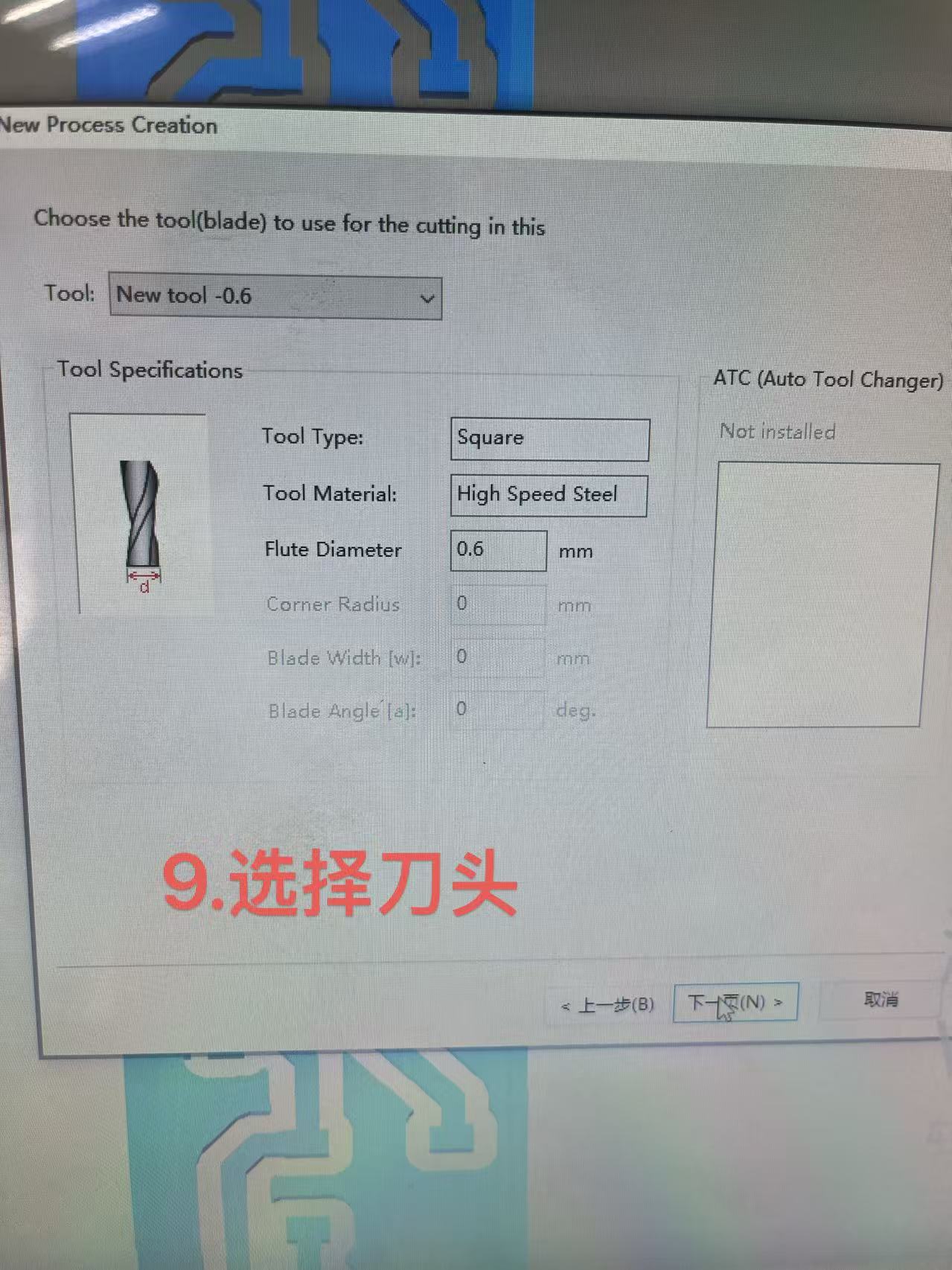

选择刀头:

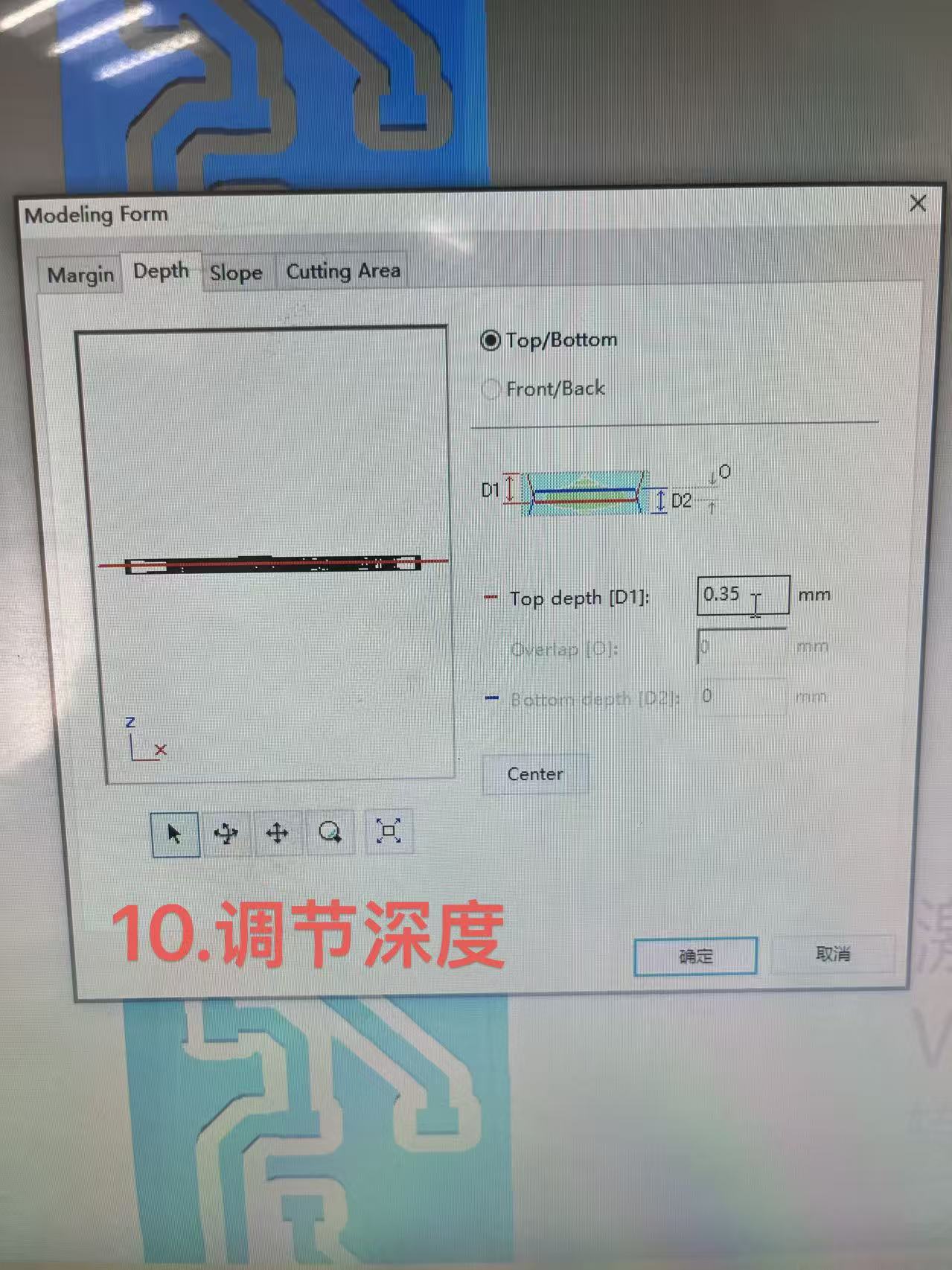

调节深度:

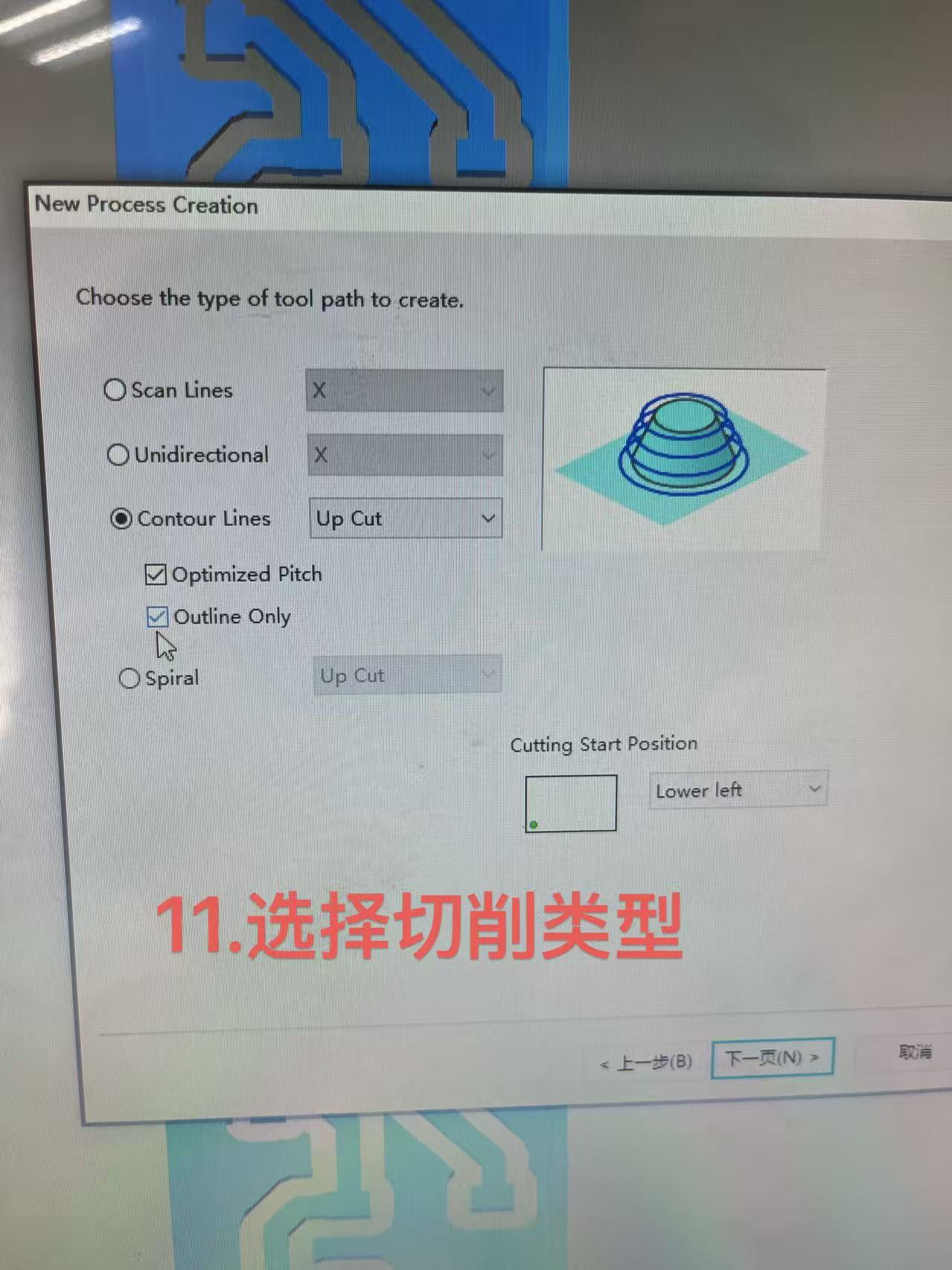

选择切削类型:

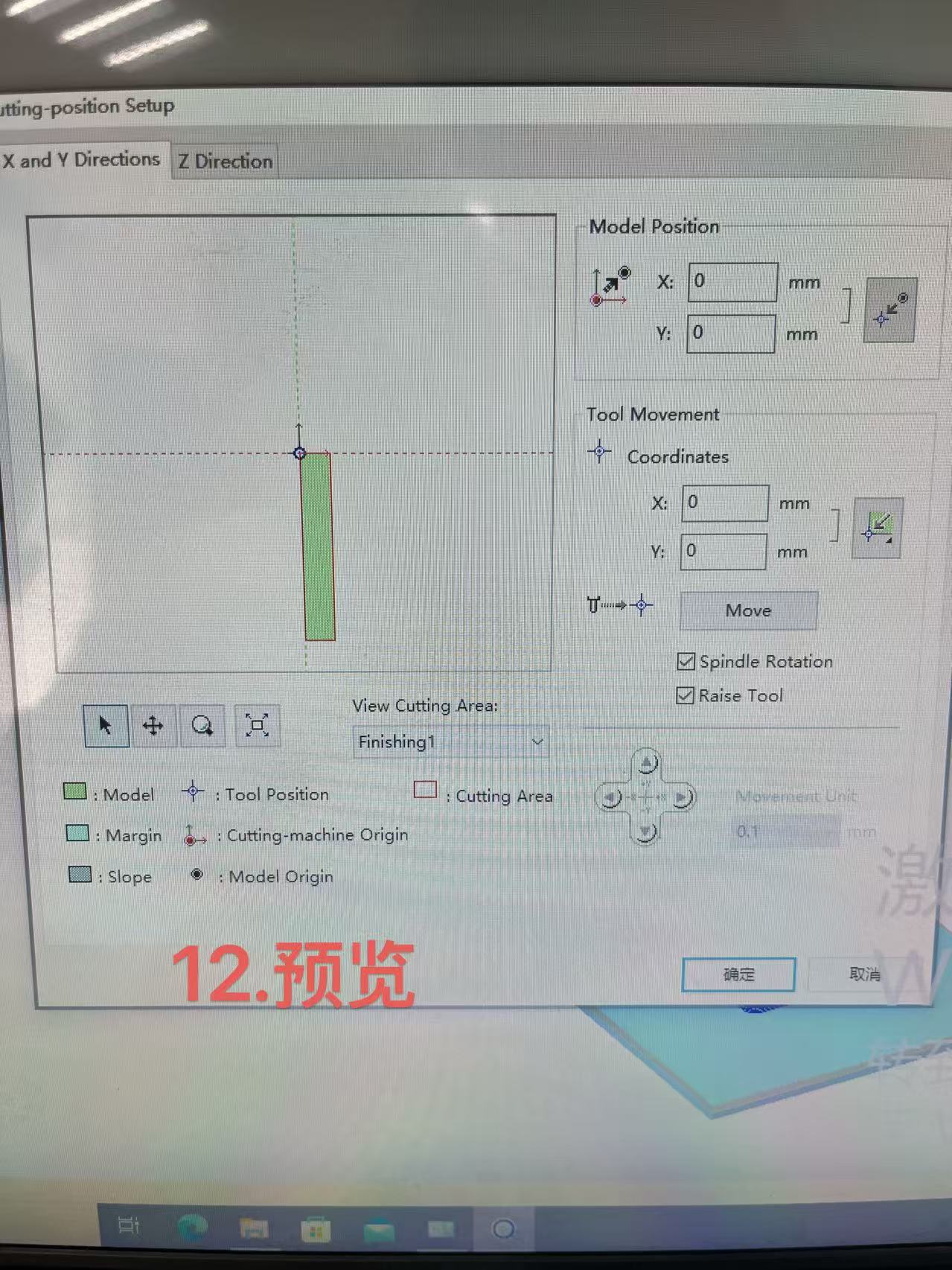

预览:

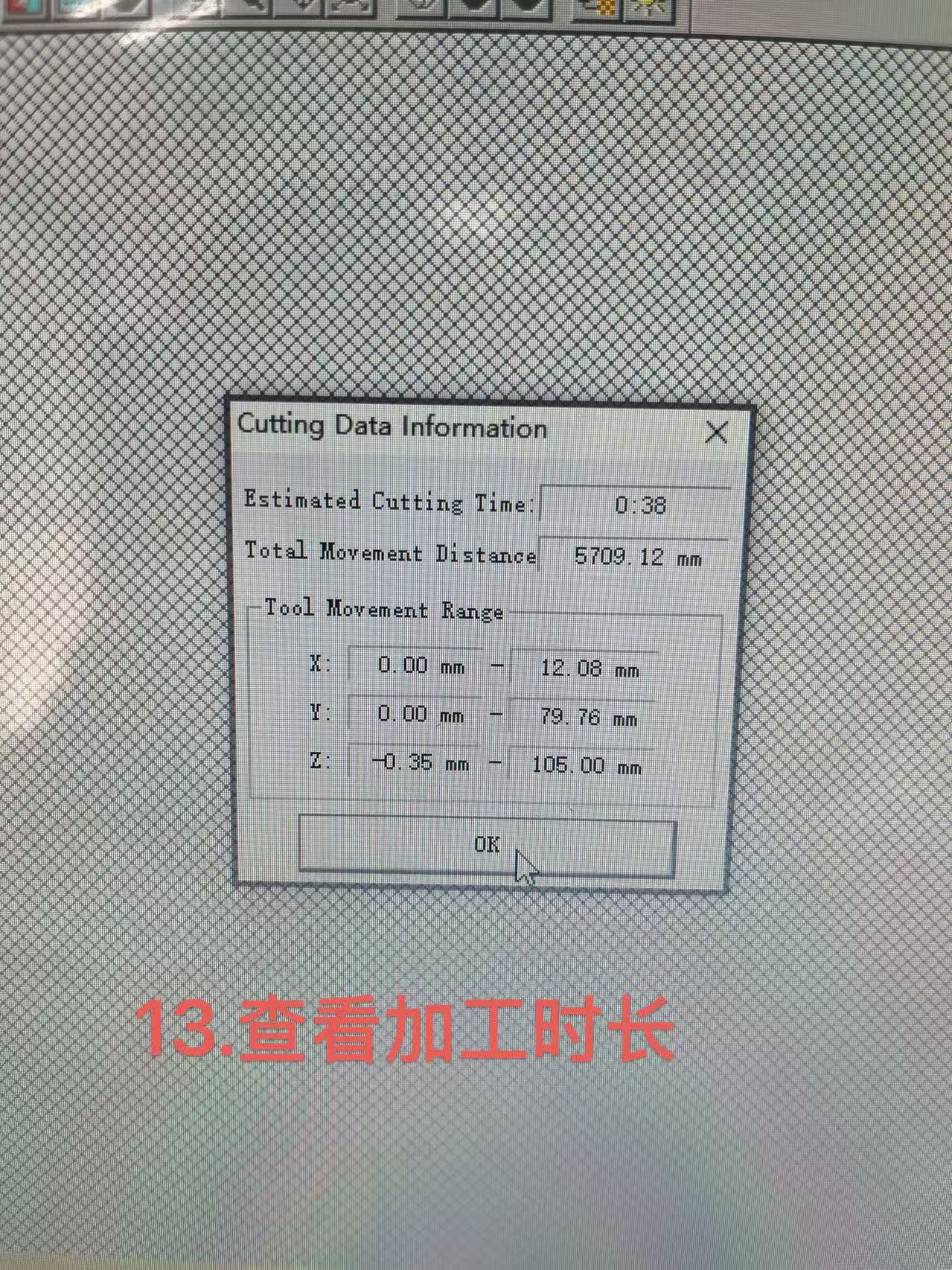

查看加工时长:

开始加工: